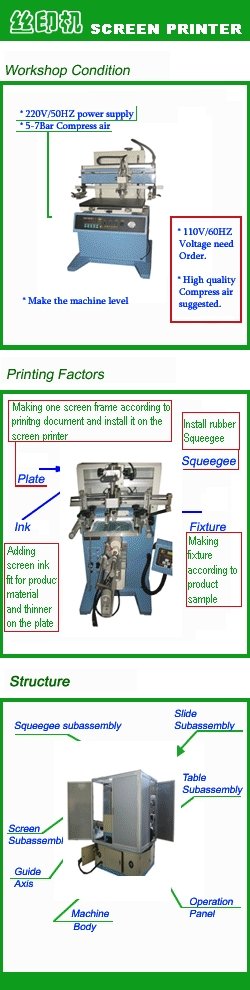

Screen printer

Used in printing flat, oval, and standard round products. It is consist of working table, screen frame combination, ink Squeegee system, operation controlling system and machine body.

l

STRUCTURE

Screen printer has a more simple structure:

1)

Working table: Install fixture and substrates. There are five kinds of working table: Flat, round, oval, T model, vacuum. T model working table and vacuum working table keep stillness when printing; other kinds of working table can move up and down when printing, In order to improve production efficency ,

conveyer working table installed on flat screen printer.this kind of screen printer is suitable printing small dimension objects.

2)

Screen frame combination: Install screen plate and store ink.When printing flat products, frame keep stillness; when printing cylinder, screen frame move from left to right.

3)

Squeegee nip combination: Install rubber squeegee and supply ink for coating on the surface of silk. Rubber blade move up-and-down, meantime ink floor move with opposition direction. When printing flat products, squeegee nip combination move left to right, when printing cylinder products, they keep stillness. Squeegee rubber finish printing and ink floor finish coating.

4)

Operation controlling system

: Most of screen printer controlled by micro-computer built in to make machine stability and easy to operate. When testing, only press simple action key and when starting automatic key to begin printing will be helpful to operate screen printer.

l

MAINLY FACTOR

1)

Screen

plate:

Making screen plate through three kinds of way: emulsion, direct film, indirect film. Different substrates need different technology parameter such as: silk tension, count, thickness of emulsion. Water base and solvent base emulsion coated according to different products.

2)

Screen ink:

Choosing solvent screen ink, UV ink and function plasma according to printing request. Ink must be test before printing.

3)

Rubber squeegee:

Ink pressed to deposit onto the products by rubber squeegee. Rectangle squeegee is for flat substrate and triangle squeegee is for cylinder substrate. Harder squeegee get more precision printing result than softer squeegee.

4)

Fixture:

It is important to make fixture according to products. Regular products need the fixture made by lathe or CNC. Complex products need the fixture made by polyester resin. Round products need same diameter transmission gear with product diameter.

l

SORTS

2. One colour, two colours, screen printer to be sorted according to max printing colour numbers. One colour screen printer print one colour one time; two colours pad printer print two colours in one product one time. One colour screen printer is simpler, but multicolor screen printer has more complex structure and volume. widely use in printing cosmetic and other industry package.

3. to be sorted according to different working table installed. Round working table screen printer print round products; oval working table one print oval bottle; T model screen printer print rigid flat products and vacuum table screen printer print paper and soft film products.

4. Different feed transmission way sort screen printer as and web-roller screen printer. Most of screen printer is single-piece screen printer.