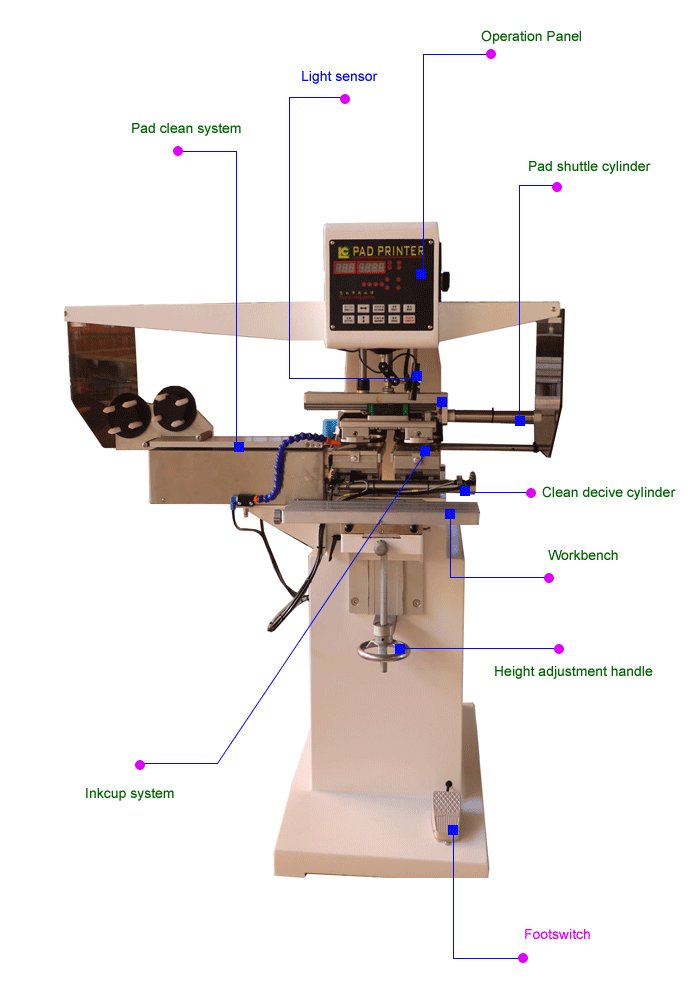

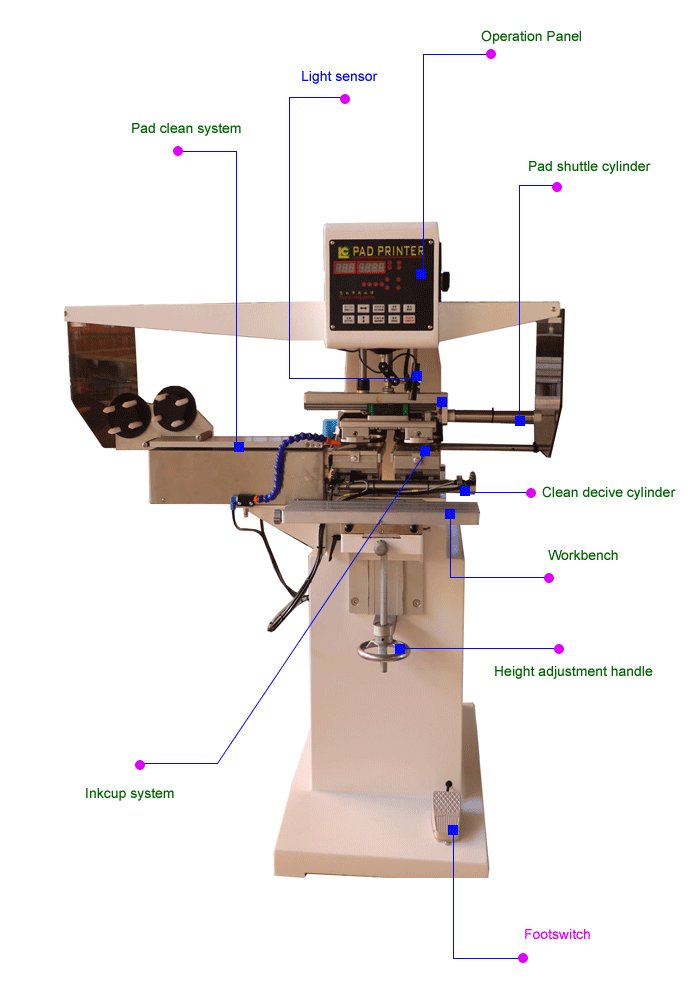

The rubber pad shuttle type pad printing machine is to install a shuttle rubber head in the lateral direction of the plastic head, so that the rubber head performs the left and right shuttle movement after the ink is sucked, and completes the two-color to multi-color printing.

The characteristics of this pad printer are:

The table does not perform a shuttle action, it is fixed so that the position remains stationary after the fabric is placed on the table.

Add a shuttle system to the rubber pad device. The pad first licks the ink above the ink tank, then moves to the top of the substrate to print the first color, and the rubber head moves to perform the second color printing.

The position where the rubber head shuttles to perform the second color printing has photoelectric sensor recognition control, which determines the overprint position of the second color by controlling the first color to determine the relative position of the second color. This overprinting method avoids the disadvantage of using the jig or the uneven edges of the fabric to cause inaccurate overprinting.