The fundamental way out to improve production efficiency is to use a fully automatic bottle cap stamping machine. The full process of the automatic bottle cap brought the bottle cap into the whole process of the bottle caps into the automation management. The speed is fast, which greatly reduces the work intensity.

After the automatic bottle cap is installed with an automatic feed device, the structure is complicated. It is fully automatically operated from the feeding, transport, location adjustment, and the landing of the mall, which increases the unit output of the hot mall by nearly 10 times.

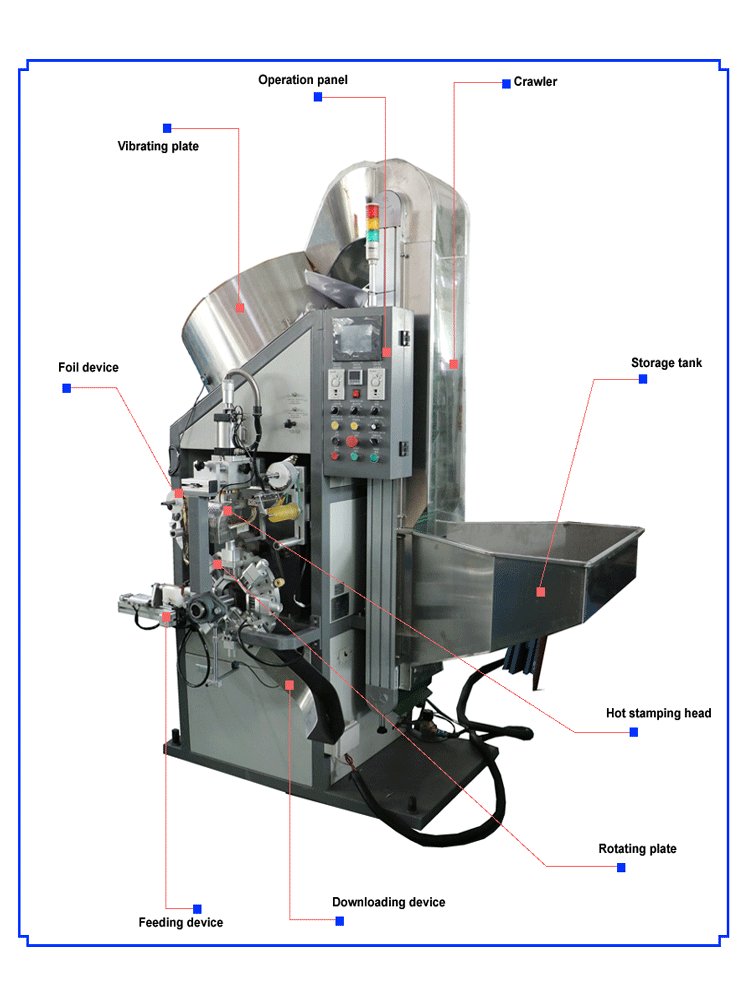

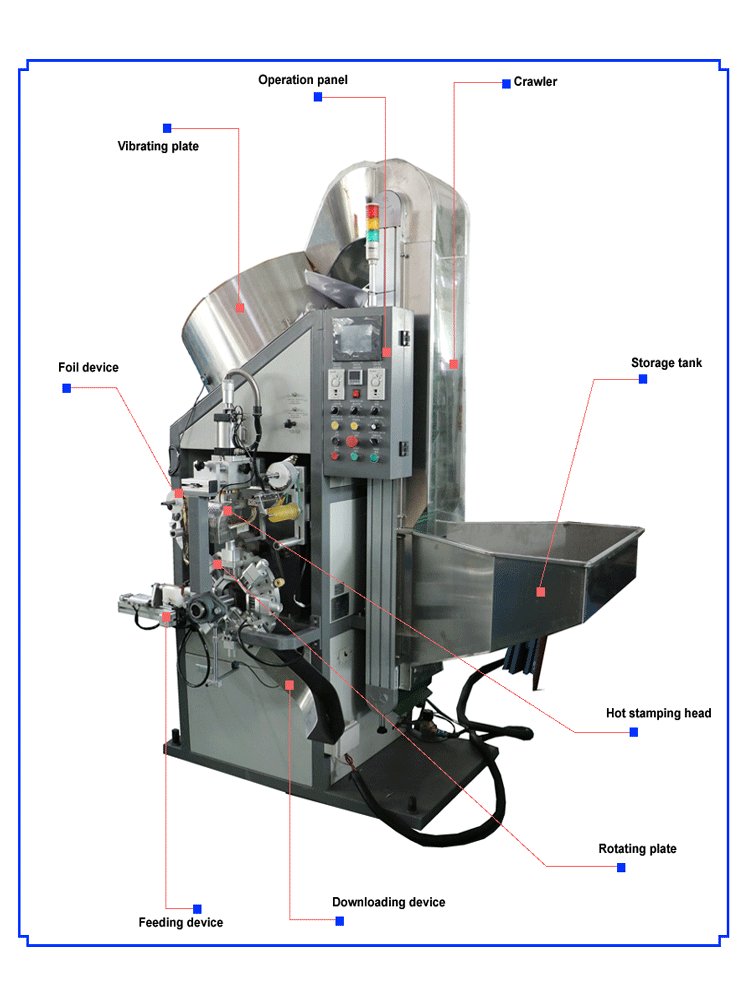

Storage device

The bottle cap is used in the storage warehouse for bottle caps for bottle caps. The bottle cap is placed at will.

Climbing

The crawling structure is used to arrange the scattered bottle caps and lines. The direction of the arranged bottle cap is uncertain. The bottle caps with inconsistencies in these openings will be sent to the transmission institution in order. The bottle cap must have the same direction, otherwise the fixture will not be able to identify these bottle caps.

Bordering agency

Transfer the bottle cap in different directions to the stamping position in the same direction is one of the most important technical links of the fully automatic gold permeal. The border selection mechanism can identify the opening of the bottle cap. The bottle cap that does not meet the golden position for reverse transmission mechanisms, and the response transmission mechanism will turn the opening direction of the bottle cap 180 degrees and enter the bronze position. In this way, the bottle cap in any direction can enter the correct bronze position to complete the bronze.

Cashier

There is not much difference between the hot golden coating mechanism and the ordinary cashmeter, but the semi -automatic bartender machine puts the bottle cap into the fixture, and then operates the machine to perform bond. Instead of fixture, and then automatically hot.

The automatic scalding machine runs fast. If it is not accurately tested in advance, large -scale bad products will be prone to. Therefore, before formal production, it is necessary to match the matching of gold and products, the location correction of the hot gold version, and the accuracy of the fixture.