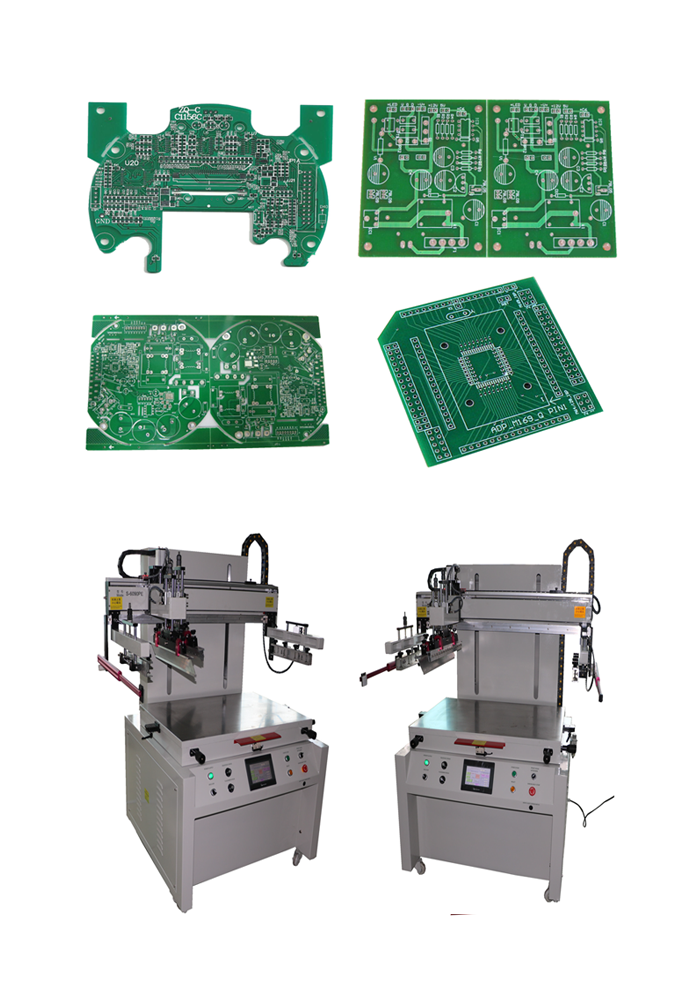

As we all know, high precision circuit board, usually its lines in error must be controlled within 0.01mm or less, ordinary pneumatic control screen printing machine is difficult to meet the requirements. The all-electric control screen printing machine because there is no air pressure fluctuations, printing stability is much higher. PS Series high-precision screen printing machine has the following structure:

1) Precision grinding plane Workbench: grinding machine of the table only after it has high flatness, circuit board printing process warpage will not occur;

2) screen scraper scraping bottom and rail lines are linear control, than the guide shaft controlled high precision screen printing machine;

3) the use of computer control and man-machine interface control system, better stability and practicality.

1. Structural features

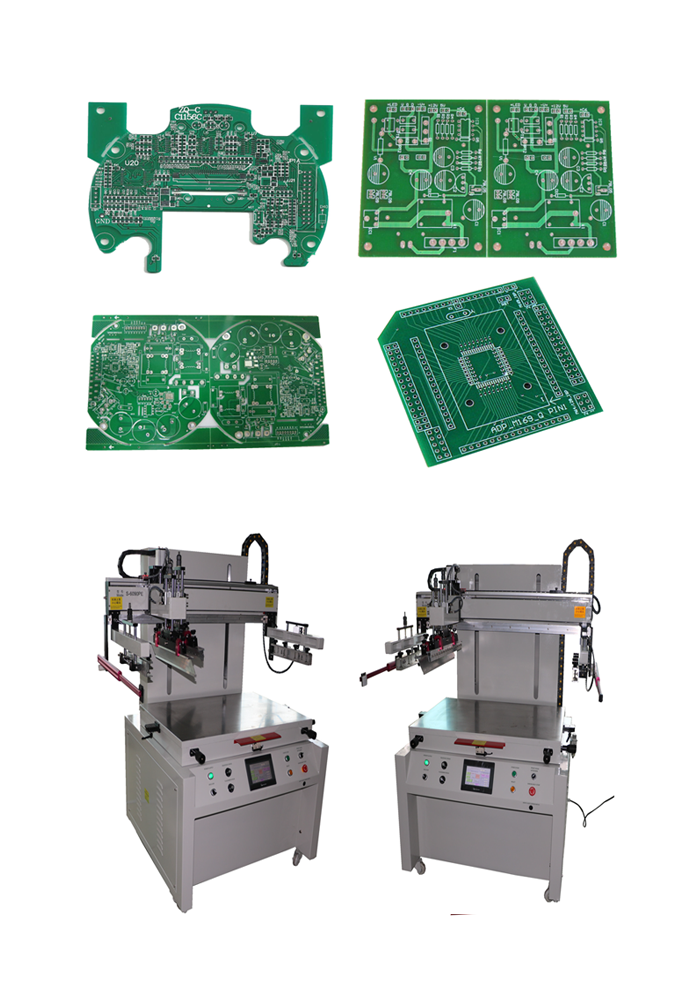

• Printing platform: It has a high-precision flat printing platform with extremely high flatness, which can ensure that the PCB board remains stable during the printing process. The platform is usually made of solid metal material and is finely processed and ground to provide a flat and stable printing base.

• Screen system: It is equipped with high-quality screens, and the tension of the screen can be precisely adjusted. For PCB multi-layer wet film solder mask sealing printing, the appropriate screen tension can ensure that the ink passes through the mesh evenly, and the material and mesh size of the screen are selected according to the characteristics of the wet film solder mask ink and the printing accuracy requirements of the PCB board.

• Scraper system: The scraper is one of the key components of screen printing. The scraper of this printer is usually made of wear-resistant and corrosion-resistant materials, such as high-quality rubber or polyurethane. The angle, pressure and speed of the scraper can be precisely controlled to ensure that the ink is evenly distributed on the screen and smoothly transferred to the PCB board.

• Positioning system: It has a high-precision positioning device that can accurately place the PCB board in the correct printing position. It may use optical positioning, mechanical positioning or a combination of the two to ensure that each layer of wet film solder mask ink can be accurately printed in the designated area of the PCB board. For the printing of multi-layer PCB boards, this precise positioning is particularly important.

2. Working principle

• First, place the PCB board on the printing platform and determine its exact position through the positioning system. Then, the screen with wet film solder mask ink is lowered and contacted with the PCB board. The scraper moves on the screen, pushing the ink through the mesh of the screen, and printing the wet film solder mask ink on the surface of the PCB board. For multi-layer PCB boards, different layers will be printed in sequence according to the design requirements, and during the printing process, it is necessary to ensure that each layer of ink can accurately cover and fill the corresponding area to play the role of solder mask and hole sealing. After printing is completed, the screen rises and the PCB board is moved out of the printing area.

3. Application advantages

• High-precision printing: It can meet the high-precision requirements of PCB boards for solder mask and hole sealing, ensure that the thickness of the ink layer is uniform and the lines are clear, thereby effectively preventing problems such as short circuits during welding and improving the quality and reliability of PCB boards.

• Multi-layer printing capability: Suitable for printing multi-layer PCB boards. Through precise positioning and control, different patterns and structures can be printed on different layers to meet the needs of complex circuit design.

• Improve production efficiency: With a high degree of automation, once the printing parameters are set, printing operations can be carried out quickly and continuously, reducing the time and error of manual operation, which is suitable for large-scale production of PCB boards.

• Guarantee ink quality: For special materials such as wet film solder mask ink, the printer can well control its distribution and thickness, so that the ink forms a high-quality protective film on the PCB board, improving the corrosion resistance and insulation of the PCB board.