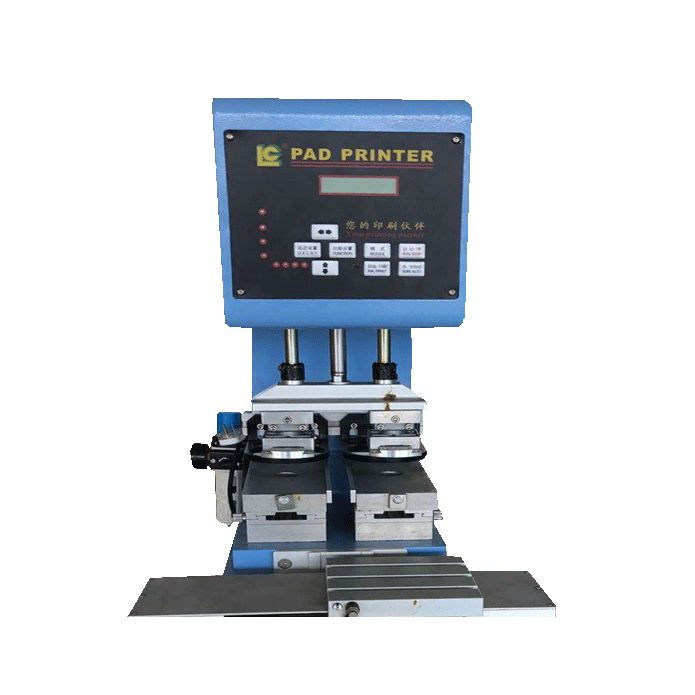

Model No.︰P2-412C

Brand Name︰LC

Country of Origin︰China

Unit Price︰US $ 3044 / pc

Minimum Order︰1 pc

Insole slipper pad printing machine

Insoles

Insoles are generally placed inside shoes to cushion, absorb sweat, increase comfort, and improve the fit of shoes. They are made of a variety of materials, including cotton, PU, EVA, etc. Cotton insoles are soft, breathable, and highly absorbent, making them more comfortable to wear; PU insoles have good elasticity and toughness; EVA insoles are light and have good cushioning performance. The shape of the insole usually fits the contour of the sole, and some also have ergonomic designs such as arch support to better protect the health of the feet.

Slippers

Slippers are mainly used for indoor and outdoor leisure wear, with a variety of styles. They can be divided into flip-flops, flip-flops, heeled slippers, etc. by type. They are made of plastic, rubber, cloth, leather, etc. Plastic and rubber slippers are usually lighter, waterproof, and easy to clean, and are commonly found in bathrooms and other places; cloth slippers are soft and comfortable, have good warmth retention, and are mostly used indoors; leather slippers have a high-end texture and are suitable for a variety of occasions. The sole designs of slippers are also different, some focus on anti-slip, and some emphasize softness to meet different usage requirements.

Two-color shuttle pad printer

Insoles usually need to be printed, and two-color pad printers are the most commonly selected equipment type.

• Principle:

The two-color shuttle pad printer has two independent ink systems (usually corresponding to two oil cups and related components) and a pad printing rubber head. When working, the rubber head will first move to the printing plate corresponding to one of the oil cups, absorb the first color of ink, and then transfer the ink to the designated part of the insole or slipper. Then, the rubber head shuttles to the printing plate corresponding to the other oil cup, absorbs the second color of ink, and accurately prints it again on the part where the first color has been printed or other preset positions. Through such a shuttle operation, the two-color printing effect is achieved, allowing the product to present a richer color combination and pattern style.

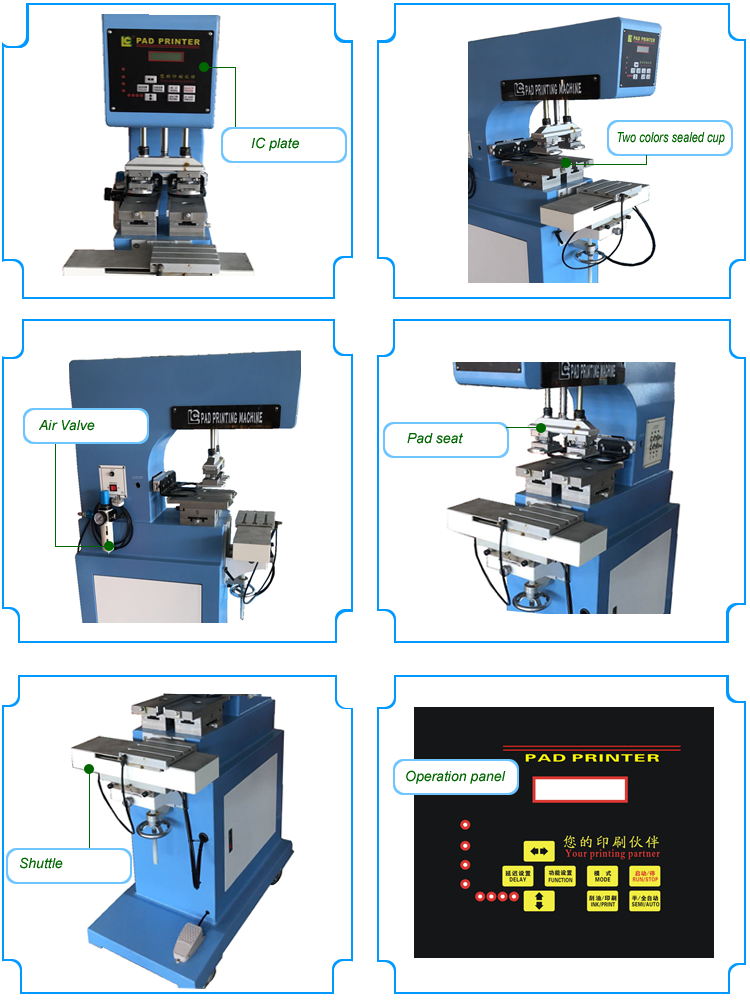

• Structural composition:

It is mainly composed of two oil cups, two sets of printing plates, a printing device, a shuttle drive mechanism, and a workbench that carries insoles or slippers. The ink cup is used to hold inks of different colors. The printing plate is engraved with corresponding patterns or words. The scraper device is responsible for scraping the ink in the oil cup evenly onto the printing plate. The pad printing rubber head realizes the absorption and transfer of ink. The shuttle drive mechanism drives the two oil cups and the printing plate of the insole or slipper to shuttle accurately to complete the printing of two colors. It adds beautiful and unique two-color decoration to the insole and slippers, and enhances the product's appearance appeal and market competitiveness.

|

Two colors pad printer with shuttle//Structure |

|

|

Working table |

Two stations Shuttle-type working table |

|

Shuttle stroke |

125mm |

|

Ink supply system |

Closed -type system |

|

Plate type and size |

10mm Thick steel plate. |

|

Pad dropping control |

Simple-cylinder , simultaneously pressing |

|

Ink drying |

Heat air |

|

Two colors pad printer//Usage and characters |

|

|

Guide |

|

|

Application fields |

Electrons, hardware, autos, toys, gifts, Plastics, household appliances, artwork, stationery, adornment, cosmetic, commodity, sport goods, decorative lightings, woodwork, office supplies, Photo Materials, Kitchen utensils, Hotel supplies, Computer, Mobile, etc., industrial field. |

|

Two colors pad printer with shuttle//Parameter |

|

|

Technical parameters |

P2-408C |

|

|

| P2-410C | |

|

|

| P2-412C | |

|

|

|

Works supply |

|

|

Package list |

|

|

H.S.Code |

8443198000 |

|

Certicate |

CE |

|

Two colors pad printer with shuttle//Advantage |

|

|

Function |

|

Summary︰

The environmental protection appeal of the pad printing machine is to use the ink supply method of the oil cup, and the ink is sealed in the oil cup to avoid the volatilization of the solvent. Two-color ink cup pad printers are the best-selling pad printers. Although high-end users will require pad printers with touch screens and more configurations, ordinary microcomputer-controlled pad printers and shuttle pad printers still occupy a large market. market share.

Two-color shuttle ink cup pad printers are introduced to the market with the size of the installed steel plate as a series. The larger the size of the steel plate, the larger the printing area. Widening the size of the steel plate in the horizontal direction means that a larger diameter oil cup needs to be selected. Extending the size of the steel plate in the transverse direction means that the size of the product that can be printed is larger. When you choose a pad printing machine, it is very important to provide your supplier with pictures of the product, dimensions, size and location of the printed pattern. In any case, if you are just getting into the field of pad printing, choosing a two-color shuttle pad printer is the most basic and probably the most cost-effective investment.