Model No.︰P2-616C

Brand Name︰LC

Country of Origin︰China

Unit Price︰US $ 4206 / pc

Minimum Order︰1 pc

Washing machine panel

Washing machine panels are usually made of engineering plastics, and common materials include ABS and PC. ABS material has good hardness, toughness and impact resistance, and is relatively cheap; PC material has higher strength, transparency and heat resistance. The design of the washing machine panel focuses on practicality and aesthetics. Generally, there will be a layout of various buttons, display screens and indicator lights to facilitate users to operate and view the working status of the washing machine.

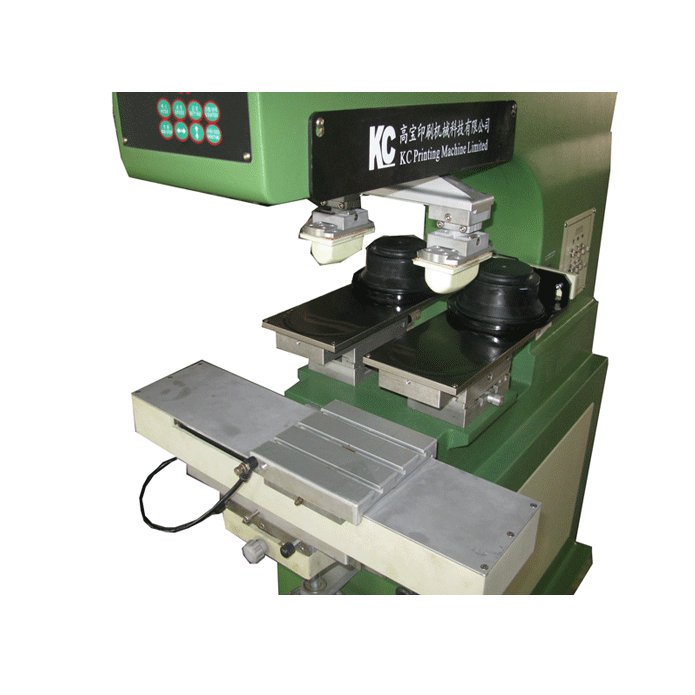

Two-color pad printing machine

The two-color pad printing machine mainly realizes two-color printing through two independent printing units. First, the first set of printing plates and oil cup systems contain patterns and texts of one color. The rubber head first dips the ink to print the first color on the washing machine panel. Then, the other rubber head dips the second set of printing plates and the graphic on the oil cup system to print another position of the washing machine panel. In order to ensure the accuracy of the overprint, the fixture and product on the shuttle workbench can be adjusted.

• Structural composition: It usually consists of a shuttle workbench, an oil cup and a printing plate system; a rubber head assembly device, an operation panel, and a pneumatic control system. The two-color shuttle pad printer is the best-selling pad printer on the market. It can print single color or two-color. Due to its simple structure, it is easy to operate and maintain. As the preferred investment for small and medium-sized enterprises, the value it creates is far greater than the cost itself.

|

Two colors pad printer with shuttle //Structure |

||

|

Working table |

Two stations Shuttle-type working table |

|

|

Shuttle stroke |

200mm |

|

|

Ink supply system |

Closed -type system |

|

|

Plate type and size |

0.3mm Thin steel sheets. |

|

|

Pad dropping control |

Simple-cylinder , simultaneously pressing |

|

|

Ink drying |

Heat air |

|

|

Two colors pad printer//Usage and characters |

||

|

Guide |

|

|

|

Application fields |

Electrons, hardware, autos, toys, gifts, Plastics, household appliances, artwork, stationery, adornment, cosmetic, commodity, sport goods, decorative lightings, woodwork, office supplies, Photo Materials, Kitchen utensils, Hotel supplies, Computer, Mobile, etc., industrial field. |

|

|

Two colors pad printer with shuttle//Parameter |

||

|

Technical parameters |

P2-614C |

|

|

||

|

P2-612C |

P2-616C |

|

|

|

|

|

Works supply |

|

|

|

Package list |

|

|

|

H.S.Code |

8443198000 |

|

|

Certicate |

CE |

|

|

Two colors pad printer with shuttle //Advantage |

||

|

Function |

|

|

Summary︰

The environmental protection appeal of the pad printing machine is to use the ink supply method of the oil cup, and the ink is sealed in the oil cup to avoid the volatilization of the solvent. Two-color ink cup pad printers are the best-selling pad printers. Although high-end users will require pad printers with touch screens and more configurations, ordinary microcomputer-controlled pad printers and shuttle pad printers still occupy a large market. market share.

Two-color shuttle ink cup pad printers are introduced to the market with the size of the installed steel plate as a series. The larger the size of the steel plate, the larger the printing area. Widening the size of the steel plate in the horizontal direction means that a larger diameter oil cup needs to be selected. Extending the size of the steel plate in the transverse direction means that the size of the product that can be printed is larger. When you choose a pad printing machine, it is very important to provide your supplier with pictures of the product, dimensions, size and location of the printed pattern. In any case, if you are just getting into the field of pad printing, choosing a two-color shuttle pad printer is the most basic and probably the most cost-effective investment.