Model No.︰PM2-100T

Brand Name︰LC

Country of Origin︰China

Unit Price︰US $ 2397 / pc

Minimum Order︰1 pc

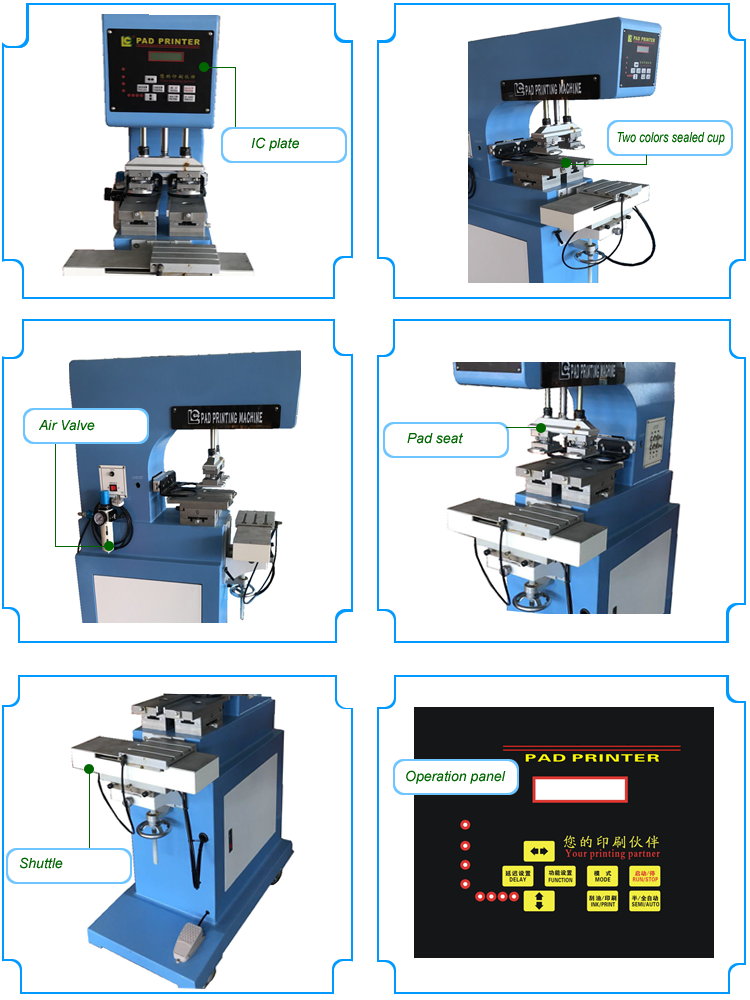

Pneumatic shuttle workbench

• The pneumatic shuttle workbench adds high efficiency and flexibility to the two-color pad printing machine. With the help of pneumatic power, it can accurately and quickly move the items to be printed, so that they can shuttle between different workstations. For example, when performing two-color pad printing, the items can be sent to the two colors of ink printing areas in turn to achieve coherent and orderly operations. Moreover, it can be well adapted to items of different sizes and shapes, ensuring the accuracy of the pad printing process and greatly improving production efficiency.

Environmentally friendly ink cup structure

• The environmentally friendly ink cup structure reflects the environmental advantages of this pad printing machine. Its design helps to better control the use and storage of ink, reduce ink volatilization and waste, and avoid pollution to the environment. At the same time, it is also convenient to add and replace ink. On the basis of ensuring the quality of pad printing, it meets the requirements of current environmentally friendly production. It is very suitable for electronic accessories pad printing with high environmental protection requirements, as well as daily necessities pad printing.

Microcomputer operation panel

• The microcomputer operation panel makes the equipment control extremely convenient. Operators can easily set the key parameters of two-color pad printing through the panel, such as the printing pressure of each color ink, printing speed, and the pressing depth of the rubber head. In the face of objects with different materials and different pattern requirements, you only need to operate the panel to quickly adjust the corresponding settings, reducing the difficulty of operation. Even novices can quickly get started and accurately perform two-color pad printing operations.

Pneumatic control system

• The pneumatic control system provides stable and accurate power support for the pad printer. It can not only accurately control the movement of the pneumatic shuttle workbench, but also fine-tune the pressing, lifting, and moving of the rubber head to ensure that the rubber head fits well with the surface of the object during two-color pad printing, and the ink can be accurately and evenly transferred to the object, achieving high-quality two-color printing effects, which is suitable for pad printing needs of various complex shapes and objects of different materials.

Hot-selling model

• As a hot-selling model, it shows that this two-color pad printer has been recognized by many users in the market. It is likely to meet the diverse needs of different industries for two-color pad printing with its stable performance, convenient operation, good pad printing quality and environmental protection, and stand out among similar products. It is widely used in various production scenarios that require two-color pad printing.

CE certification

• CE certification means that this two-color pad printer meets the relevant European safety, health, environmental protection and other standards. This not only represents its reliable quality and high safety, which makes users feel more assured, but also lays the foundation for its entry into the European market and other international markets that recognize CE standards, and indirectly reflects its standardization and high quality in design and manufacturing.

Wide range of uses

• The reason why this two-color pad printer is widely used is that it can be applied to product pad printing in many industries. In the electronics industry, it can print logos and patterns for electronic accessories; in the gift industry, it can add two-color decorative elements to gift boxes; in the daily necessities industry, two-color pattern pad printing of products such as toothbrushes and cups is also a piece of cake, meeting the personalized and aesthetic needs of different products for two-color pad printing.

Applicable scenarios

• Applicable to various production scenarios that require two-color pad printing on the product surface to improve the aesthetics and display brand information, such as electronic product manufacturers, gift factories, daily necessities processing factories, etc. As long as it involves two-color pad printing needs, it can play an excellent role with its many advantages.

|

Two colors pad printer with shuttle//Structure |

|

|

Working table |

Two stations Shuttle-type working table |

|

Shuttle stroke |

125mm |

|

Ink supply system |

Closed -type system |

|

Plate type and size |

10mm Thick steel plate. |

|

Pad dropping control |

Simple-cylinder , simultaneously pressing |

|

Ink drying |

Heat air |

|

Two colors pad printer//Usage and characters |

|

|

Guide |

|

|

Application fields |

Electrons, hardware, autos, toys, gifts, Plastics, household appliances, artwork, stationery, adornment, cosmetic, commodity, sport goods, decorative lightings, woodwork, office supplies, Photo Materials, Kitchen utensils, Hotel supplies, Computer, Mobile, etc., industrial field. |

|

Two colors pad printer with shuttle//Parameter |

|

|

Technical parameters |

PM2-100T |

|

|

| PM2-150T | |

|

|

| PM2-200T | |

|

|

|

Works supply |

|

|

Package list |

|

|

H.S.Code |

8443198000 |

|

Certicate |

CE |

|

Two colors pad printer with shuttle//Advantage |

|

|

Function |

|

Summary︰

In European countries, users tend to buy pad printers with closed ink cups. This type of pad printer is equipped with a structure similar to a closed oil cup to store ink to reduce VOC volatilization during printing. In the pad printing industry, UV pad printing inks and water-based inks are used very little, and solvent-based inks are mainly used. The solvent contained in the ink volatilizes into the air and will cause certain damage to the operator’s respiratory system. Ink is an effective way to reduce this damage. Since the ink is enclosed in a relatively closed space, its viscosity and printability will also maintain a certain degree of stability, which is beneficial to pad printing quality.