Model No.︰P2-408C

Brand Name︰LC

Country of Origin︰China

Unit Price︰US $ 2397 / pc

Minimum Order︰1 pc

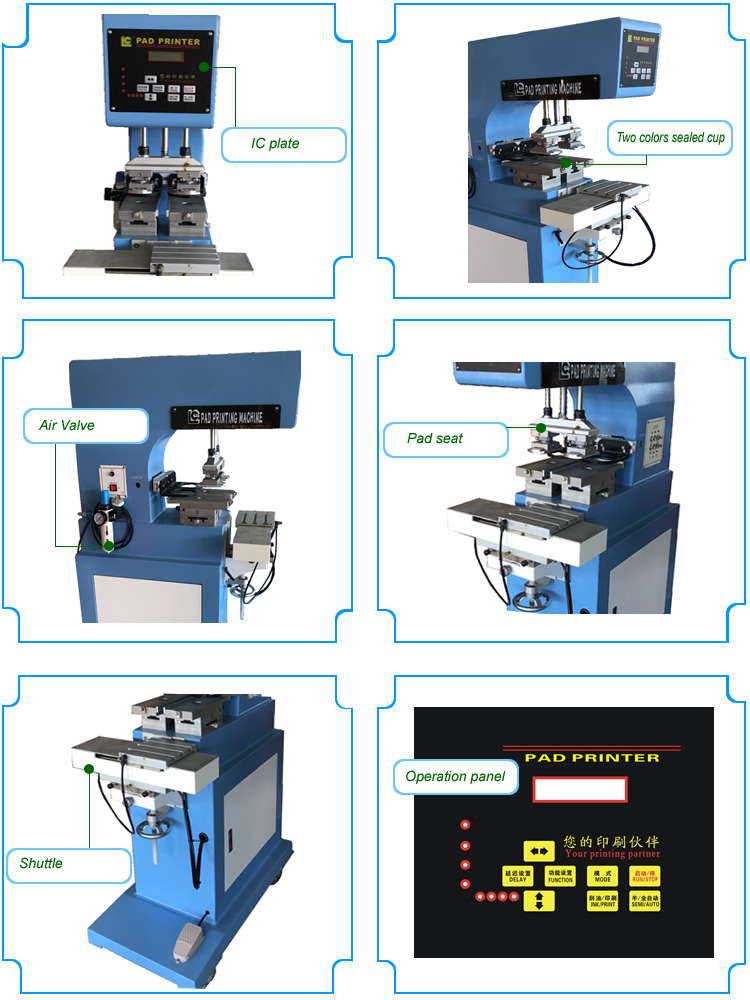

Bicycle Accessories Ink Cup Pad Printer:

Working Principle

The ink cup pad printer mainly uses the rubber head to dip the ink supplied to the printing plate by the oil cup, and then transfers the ink pattern to the surface of objects such as bicycle accessories, motorcycle accessories or automobile accessories. The two-color ink cup ink supply system can provide ink for the two-color printing plate respectively, and the independent oil cup push system accurately controls the movement of the oil cup to make the ink supply more accurate. After the rubber head dips in different colors of ink, the pattern is transferred to the object in turn to achieve two-color printing.

Structural Features

• Microcomputer Control Panel:

• Provides precise operation control. Users can set multiple parameters such as the movement trajectory of the rubber head, ink dipping time, transfer pressure, and switching sequence of two-color inks through the panel. For different accessory materials (such as metal auto accessories and plastic bicycle accessories), the parameters can be easily adjusted on the panel to achieve the best printing effect.

• Multiple printing programs can be stored. When encountering accessories of different shapes and sizes, the corresponding program can be directly called, which greatly improves work efficiency.

• Two-color ink cup ink supply:

• It can provide two colors of ink at the same time, which broadens the functions of printing. For accessories that require two-color patterns, such as automotive accessories with brand logos and decorative patterns, the two-color ink cup ink supply system can meet the needs well.

• Each ink cup can independently control the ink volume and ink supply frequency to ensure that the ink supply of the two colors is stable and uniform, and there will be no excessive or insufficient ink in one color.

• Independent ink cup push system:

• Precisely control the movement of each ink cup, and can flexibly adjust the position and ink supply of the ink cup according to the printing progress and pattern requirements. For example, when printing a two-color pattern, the push system can accurately control which color to supply first and the supply amount of each color ink to ensure the quality of the two-color pattern.

• The independent system is also easy to maintain and debug. When a problem occurs in one ink cup, it will not affect the normal operation of the other ink cup.

• Shuttle table:

• The shuttle table can quickly send accessories in and out of the printing area. While printing one accessory, the next accessory to be printed can be placed on the other side of the workbench, which improves work efficiency.

• The shuttle workbench can accurately position the accessories, ensuring that each accessory enters the printing position accurately and the printing pattern is accurately positioned, which is especially important for irregularly shaped bicycle, motorcycle and automobile accessories.

|

Two colors pad printer with shuttle//Structure |

|

|

Working table |

Two stations Shuttle-type working table |

|

Shuttle stroke |

125mm |

|

Ink supply system |

Closed -type system |

|

Plate type and size |

10mm Thick steel plate. |

|

Pad dropping control |

Simple-cylinder , simultaneously pressing |

|

Ink drying |

Heat air |

|

Two colors pad printer//Usage and characters |

|

|

Guide |

|

|

Application fields |

Electrons, hardware, autos, toys, gifts, Plastics, household appliances, artwork, stationery, adornment, cosmetic, commodity, sport goods, decorative lightings, woodwork, office supplies, Photo Materials, Kitchen utensils, Hotel supplies, Computer, Mobile, etc., industrial field. |

|

Two colors pad printer with shuttle//Parameter |

|

|

Technical parameters |

P2-408C |

|

|

| P2-410C | |

|

|

| P2-412C | |

|

|

|

Works supply |

|

|

Package list |

|

|

H.S.Code |

8443198000 |

|

Certicate |

CE |

|

Two colors pad printer with shuttle//Advantage |

|

|

Function |

|

Summary︰

The two-color pad printer is the semi-automatic pad printer with the largest sales volume. It can print more than 40% of small size products, suitable for those who have just entered the pad printing industry to engage in pad printing. According to relevant data, most products only print one color or two colors, so the two-color pad printer is undoubtedly the type that can complete the most printing tasks and has the lowest cost.

The shuttle-type two-color pad printer is equipped with a shuttle table with two stations, which in turn can clamp a product for printing, and the overprinting accuracy is relatively high. The video shows the use of a two-color shuttle pad printer to print a lighter.