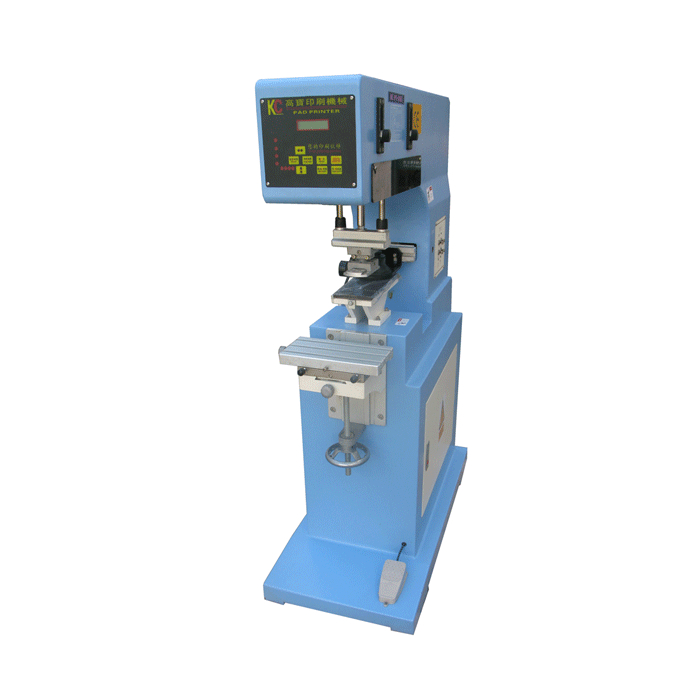

Model No.︰P1-410C

Brand Name︰LC

Country of Origin︰China

Unit Price︰US $ 1779 / pc

Minimum Order︰1 pc

Working principle

• Workbench and positioning part: The three-dimensional workbench can realize multi-directional precise movement. Through the motor and other driving devices, the position can be flexibly adjusted in three dimensions of X, Y, and Z axes, and the specific parts that need to be printed on the substrates such as cloth labels and clothes can be accurately positioned. The infrared positioning device further assists the positioning. It emits infrared rays to determine the exact position of the substrate and the relative position relationship between the rubber head and the substrate to ensure the accuracy of the printed pattern.

• Ink supply part: The ink supply method is adopted, and the oil cup is filled with pad printing ink of the corresponding color. When the rubber head descends into the oil cup to dip the ink, the internal structure of the oil cup cooperates with the scraper and other components to allow the rubber head to evenly dip the appropriate amount of ink and scrape off the excess ink, so that the amount of ink carried by the rubber head meets the printing requirements, and prepares for the subsequent accurate transfer of ink to the substrate.

• Rubber head movement part: The left and right shuttle structure of the rubber head is driven by the power mechanism, so that the rubber head can shuttle in the left and right directions according to the set path and rhythm. In two-color printing, the pad first dips the first color ink from one side, moves to the top of the substrate for initial printing, then shuttles to the other side to dip the second color ink, and then returns to the corresponding position of the substrate to complete the two-color overprinting, realizing the superposition of colors and the complete presentation of patterns.

• Operation control: Rely on the microcomputer operation panel for comprehensive control. The operator can set many parameters such as the moving speed of each axis of the three-dimensional workbench, the speed and frequency of the pad shuttle left and right, the ink supply of the oil cup, and the printing pressure on the panel. The operator can also flexibly adjust the entire pad printing process according to the different materials and printing pattern requirements of the cloth label and clothes, and can view the working status of the machine in real time through the panel.

Application scenarios

• Clothing industry: used to print brand logos, personalized patterns, decorative elements, etc. on various types of clothes (such as T-shirts, sweatshirts, work clothes, etc.), enrich the pattern colors through two-color printing, create a unique clothing appearance, and meet the needs of personalized customization and brand promotion.

• Fabric label production field: two-color printing of fabric labels (such as clothing labels, backpack labels, etc.), such as printing trademarks, product information, pattern logos, etc., to improve the recognition and aesthetics of fabric labels, so that they can better play the role of identification and decoration.

Advantages

• Accurate positioning and printing: The three-dimensional workbench combined with the infrared positioning device ensures the high precision of the printing position. The left and right shuttle structure of the rubber head can accurately realize the two-color overprinting, so that the printed pattern can be presented on the fabric label and clothes clearly and accurately, meeting the design requirements.

• Uniform and stable ink supply: The ink supply method of the oil cup ensures that the amount of ink dipped by the rubber head each time is uniform and appropriate, which helps to maintain stable printing quality and avoid printing defects caused by too much or too little ink.

• Convenient and flexible operation: The microcomputer operation panel allows operators to easily master and adjust many parameters, conveniently and quickly adapt to different fabric labels, clothing materials and printing needs, and improve work efficiency and printing effects.

|

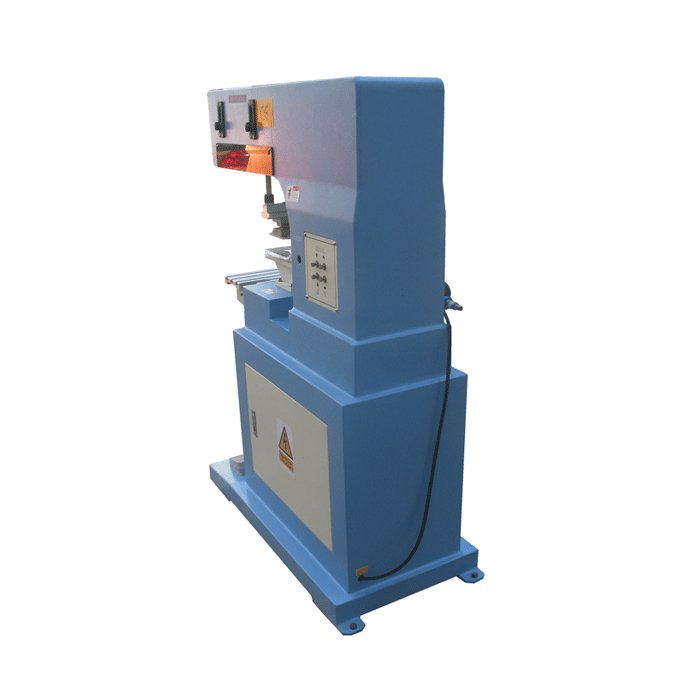

One color pad printer //Structure |

|

|

Working table |

Standard working table with 3-size adjustment |

|

Ink supply system |

Closed -type system |

|

Plate type |

10mm Thick steel plate. |

|

Pad dropping control |

Simple-cylinder , simultaneously pressing |

|

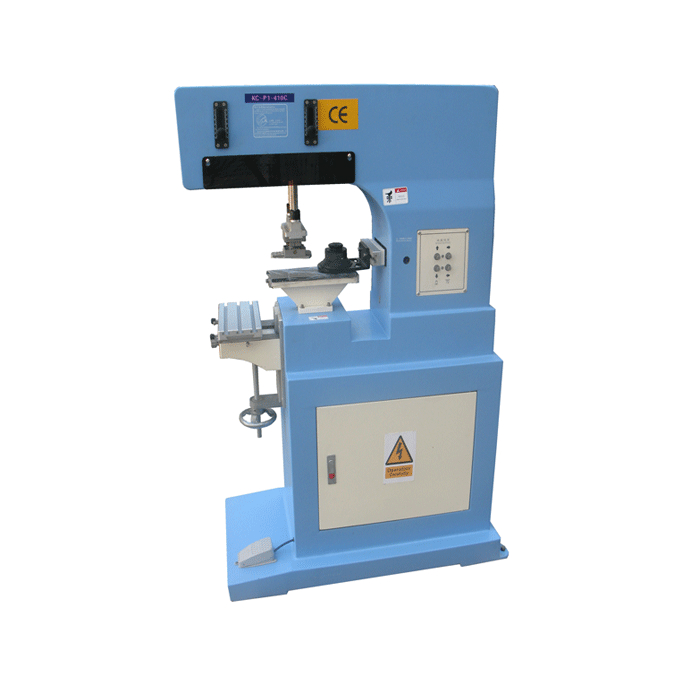

One color pad printer//Usage and characters |

|

|

Guide |

|

|

Application fields |

Electrons, hardware, autos, toys, gifts, Plastics, household appliances, artwork, stationery, adornment, cosmetic, commodity, sport goods, decorative lightings, woodwork, office supplies, Photo Materials, Kitchen utensils, Hotel supplies, Computer, Mobile, etc., industrial field. |

|

One color pad printer //Parameter |

|

|

Technical parameters |

P1-408C |

|

|

| P1-410C | |

|

|

| P1-412C | |

|

|

|

Works supply |

|

|

Package list |

|

|

H.S.Code |

8443198000 |

|

Certicate |

CE |

|

One color pad printer //Advantage |

|

|

Function |

|

Summary︰

Monochrome pad printer, as the name implies, can only print one color at a time. It has a set of ink supply device and a set of printing plate system, and the structure is relatively simple. But the monochrome pad printer also has an obvious advantage in that the size of its printed products is much larger, and the printing area is also large, because there are no restrictive accessories around the ink supply system, it can be installed with a large oil pan or Oil cup.

Another important development direction for semi-automatic pad printers is to install a loading system and an unloading system to automate the printing process. More and more users transform their pad printers and have produced good effects.