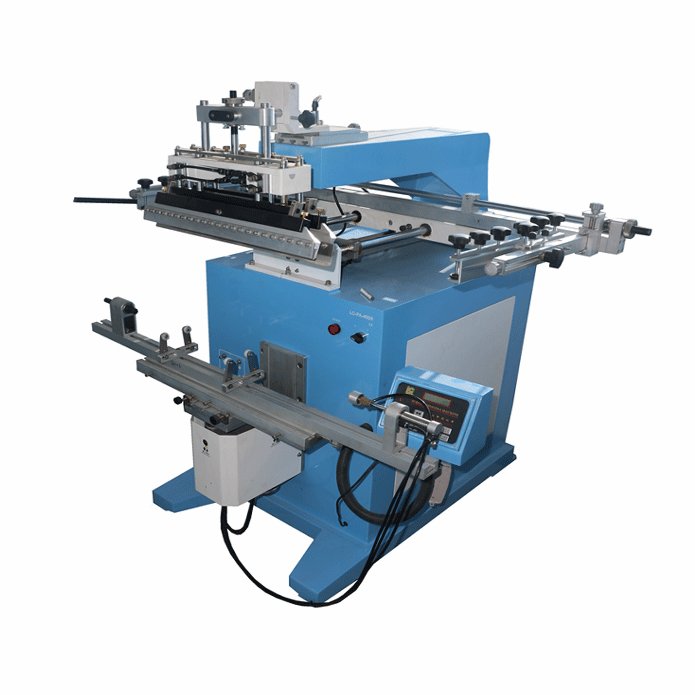

Model No.︰S-400H

Brand Name︰LC

Country of Origin︰China

Unit Price︰US $ 4162 / pc

Minimum Order︰1 pc

Fishing rod screen printer:

Main types

• Long rod screen printer: Designed for long fishing rods, the front and rear drive of the screen is driven by a cylinder, and the lifting of the print head and the lifting table are driven by a cylinder. It can print fishing rods up to 2.5 meters long. It uses PLC plus touch screen control, which is simple to operate and stable.

Working principle

The designed pattern or text is made into a screen and installed on the screen printer. Then, ink is applied to the screen, and the ink is transferred to the surface of the fishing rod through the mesh of the screen by squeezing the scraper or scraper, thereby forming the required pattern or text.

Features and advantages

• High-precision printing: It can achieve accurate pattern and text printing, ensure printing quality and clarity, and make the logos, patterns, etc. on the fishing rod more exquisite and durable.

• Adapt to different materials: It can be printed on fishing rods of different materials, such as glass fiber, carbon fiber, etc., to meet diverse needs.

• Improve production efficiency: It has a high degree of automation, can quickly complete the printing of fishing rods, improve production efficiency, and reduce labor costs.

• Easy to operate: Using advanced control systems, such as PLC plus touch screen control, the operation is simple and easy to understand, reducing the labor intensity and technical threshold of operators.

Application areas

• Brand logo printing: Printing brand logos, models and other information on fishing rods helps to improve brand awareness and product recognition.

• Decorative pattern printing: Various exquisite decorative patterns such as flowers, animals, landscapes, etc. can be printed to increase the beauty and artistic value of fishing rods and meet the personalized needs of consumers.

• Scale line printing: Used to print scale lines on fishing rods, so that anglers can more accurately judge information such as the telescopic length and water depth of the fishing rod.

|

S-400H Long-rod cylinder screen printing machine//Structure |

|

|

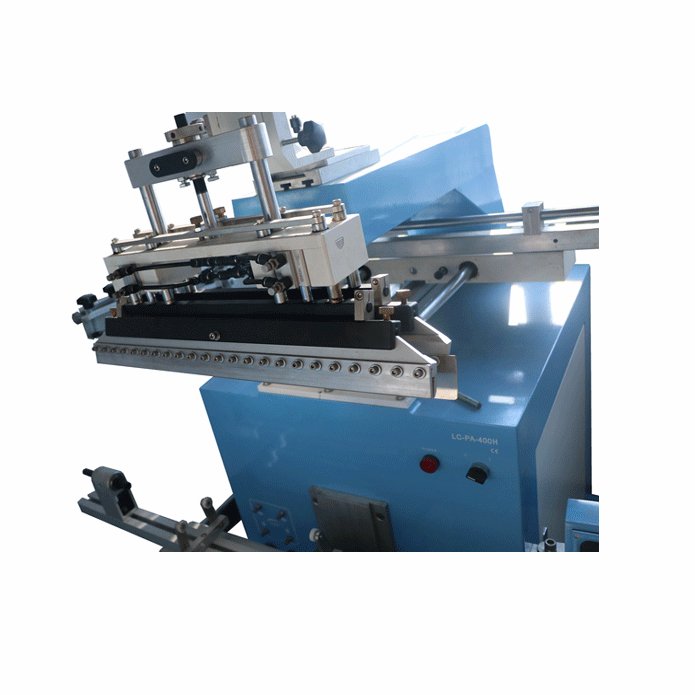

Working table |

Cylinder workbench |

|

Actions |

Up-down of working table |

|

To be printed |

|

|

Squeegee stroke |

Adjust the Limited switch |

|

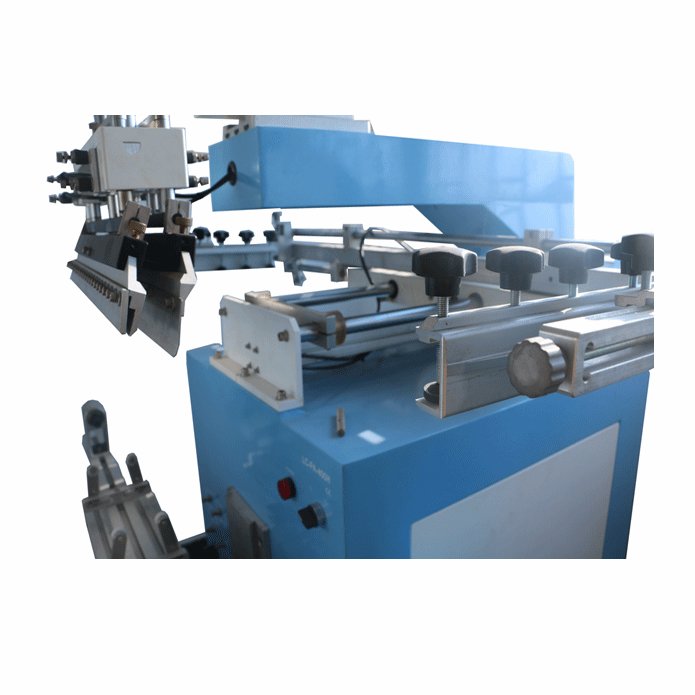

Squeegee and screen plate control |

High precision guide shaft |

|

S-400H Multi-function screen printing machine//Usage and characters |

|

|

Guide |

|

|

Application |

Plastics soft tubes, Bottles, containers, Bucket, Cosmetic case, any Cylinder-object, Oval-object. |

|

S-400H Multi-function screen printing Machine //Parameters |

|

|

Technical parameters |

|

|

Works supply |

|

|

Package parameters |

|

|

H.S.CODE |

8443198000 |

|

Certificate |

CE |

|

S-400H Long -rod cylinder screen printing Machine//Advantage |

|

|

Function |

|

Summary︰

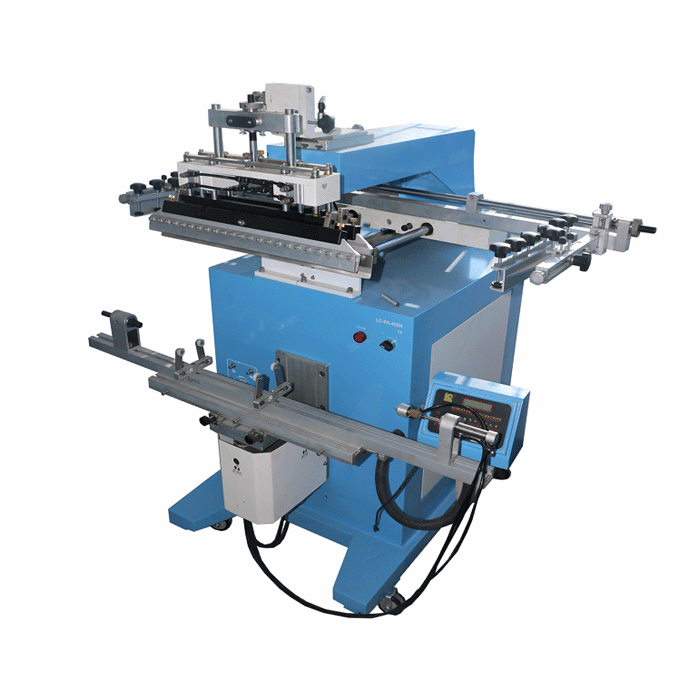

1. The curved screen printing machine can print almost all cylinders. In theory, no matter how large the diameter and length, it can be printed, but the size of the machine is larger.

2.The general curved screen printing machine is designed according to the length of the cylinder within 400mm, and adopts the structure in which the length direction of the substrate and the moving direction of the screen are perpendicular.

3. If the structure is used for printing a cylinder having a length of more than 400 mm, the screen printing opportunity is unstable and inconvenient to operate.

4. So what kind of screen printing machine should the cylindrical product with a length of more than 400mm be used?

5. Generally adopted in the Chinese market is a structural form in which the product length direction and the fuselage are parallel. When printing, the product rotates and the direction of the squeegee is perpendicular to the body. Since the product can be extended infinitely to both ends without being restricted, the length of the machine printing can be greatly improved.

6. This screen printing machine is ideal for fishing rods, golf clubs, long tools, glass tubes, etc.