Model No.︰M-02XIR

Brand Name︰LC

Country of Origin︰-

Unit Price︰US $ 3603 / pc

Minimum Order︰1 pc

Far infrared drying line after printing of hardware products:

Working principle

The far infrared drying line is a way of heating by far infrared radiation. The far infrared can be absorbed by the object and converted into heat energy, so that the inside and surface of the object are evenly heated, thereby quickly evaporating the residual solvents and moisture after printing, and achieving the drying effect.

Applicable advantages

• Hardware products: After printing such as hardware tools and decorative hardware, the far infrared drying line can efficiently dry the ink, avoid dust contamination caused by long-term natural drying, and ensure that the printed pattern is clear and firm.

• Auto parts: After printing logos on accessories such as automotive interiors and dashboards, it can accurately control the drying temperature and time, ensure printing quality, improve production efficiency, and meet the needs of large-scale production of auto parts.

• Furniture products: Whether it is pattern printing on wooden furniture or printing and decoration of some metal furniture parts, the far infrared drying line can heat and dry deeply inside, reduce surface defects caused by uneven drying, and improve the overall aesthetics of the furniture.

• Household appliances: After the brand logo, function description and other contents are printed on the outer shell of refrigerators and washing machines, it can be quickly dried through it, which helps to speed up the production process, make the printing effect lasting, and not easy to fade or wear during subsequent use and transportation.

Equipment features

• High drying efficiency: Compared with traditional methods such as natural drying, it can complete the drying task in a short time, greatly shortening the production cycle.

• Good temperature uniformity: It can ensure that all parts of the dried items are heated more evenly, so that the drying effect is consistent and the printing quality is improved.

• Environmental protection and energy saving: The energy consumption is relatively low, and no pollutants such as exhaust gas are generated, which meets the requirements of environmental protection production.

Key points for purchase

• Drying line length and power: The appropriate length and power configuration should be determined according to the production scale, product size, etc. to ensure that the batch drying needs can be met.

• Temperature adjustment range: Different products have different drying temperatures after printing. It is necessary to select equipment with a wide and accurate temperature adjustment range to adapt to various products.

• Automation degree: Give priority to those with automatic control systems, which are convenient for accurate control of parameters such as drying time and temperature, and are easier to operate.

|

IR Drying Machine//Usage and characters |

||

|

Guide |

|

|

|

Application fields |

|

|

|

IR Drying tunnel //Parameter |

||

|

Technical parameters |

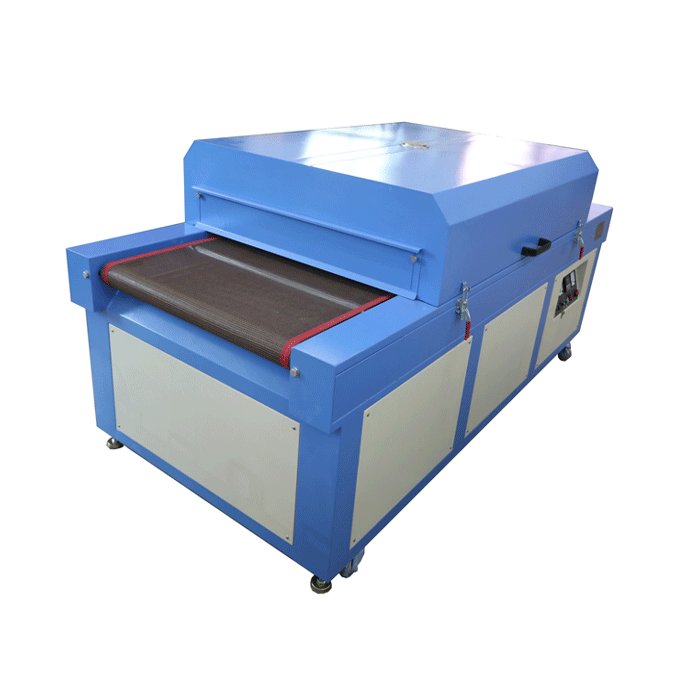

M-02XIR far-infrared Drying conveyer

|

|

|

Works supply |

|

|

|

Package list |

Package Dimension:

|

|

|

H.S.Code |

8443198000 |

|

|

Certificate |

CE |

|

|

IR Drying tunnel //Advantage |

||

|

Function |

heated with far-infrared ceramic heating rod and hot wind circuit make printed object dry evenly in the shortest time. Thus save power;

telflon coated conveyor belt can work properly and durable in high temperature.

The conveyor is driven by stepless change speed motor. Therefore, running speed of conveyor can be set arbitrary, Thus, The dryer can dry diffrent thickness object.

openable covers on both side of heating room. Ceramic heating rod can be easily replaced by simply opening the cover of heating room.

Heating temperature can be set to any temperature between room temperature to 300 degree. Tolerance of temperature is in +/-5 degree. |

|

Summary︰

Ink drying is an important indicator to measure the printing quality. The more common ways of ink drying are heat drying and UV drying. Heat drying is the drying method of solvent-based ink. In order to maintain the continuous delivery of products, the most common way to dry solvent-based ink is to use a tunnel furnace for processing. The tunnel drying furnace consists of a conveyor belt that can circulate and a device that can generate infrared rays. Composition, the product will be placed on the conveyor belt, driven by the motor, the conveyor belt will be transported to the infrared lamp at a constant speed to receive irradiation, and the solvent in the ink will be evaporated and sent to the outside.

Tunnel dryer can be connected with pad printing machine, screen printing machine, widely used in various types of plastic, glass, and clothing printing industries.