Model No.︰-

Brand Name︰KC

Country of Origin︰China

Unit Price︰US $ 20 / pc

Minimum Order︰1 pc

The following materials are required to make the screen:

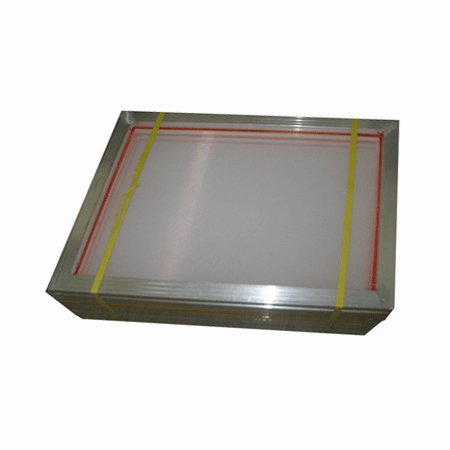

• Screen frame material:

Aluminum screen frame: light weight, not easy to rust, moderate strength and stability, is a commonly used material, suitable for a variety of printing scenarios.

• Screen material:

Polyester screen: good chemical stability, acid, alkali and other chemical substances, strong adaptability to ink, can be used for printing a variety of inks, moderate price.

Nylon screen: excellent elasticity, can fit well on curved surfaces and elastic objects for printing, good wear resistance, but slightly poor chemical resistance.

Stainless steel screen: extremely high precision, precise mesh size, strong wear resistance and corrosion resistance, suitable for high-precision, long-term use of screens, but the price is relatively high.

• Photosensitive adhesive material:

Diazo photosensitive adhesive: fast photosensitivity, can complete the exposure process in a short time, high resolution, clear edges and high precision of printed patterns, but the storage conditions are relatively strict.

Single-liquid photosensitive adhesive: easy to operate, no complicated configuration process is required, but its photosensitivity and resolution are slightly worse than diazo photosensitive adhesive.

• Coating tool materials:

Scraper: used for manual coating of photosensitive adhesive, evenly coating the photosensitive adhesive on the screen, generally made of rubber or plastic, with different hardness and sizes to choose from.

Automatic glue coating machine: used for large-scale production of screens or high requirements for glue coating uniformity, which can improve glue coating efficiency and quality.

• Film materials:

Film: a common material for making printing pattern negatives, with high resolution and clear patterns, and can accurately transfer pattern information to the photosensitive adhesive.

• Auxiliary materials:

Tension meter: used to measure the tension of the screen during the stretching process to ensure that the screen tension is uniform and appropriate, and to ensure printing accuracy.

Screen sealing glue: used to seal the non-printing area of the screen to prevent ink penetration and improve the durability of the screen.

Developer and cleaning solution: The exposed screen needs to be developed in a developer to dissolve the unexposed photosensitive resin and form a transparent part of the printed pattern. The remaining photosensitive resin and developer are then removed with a cleaning solution.

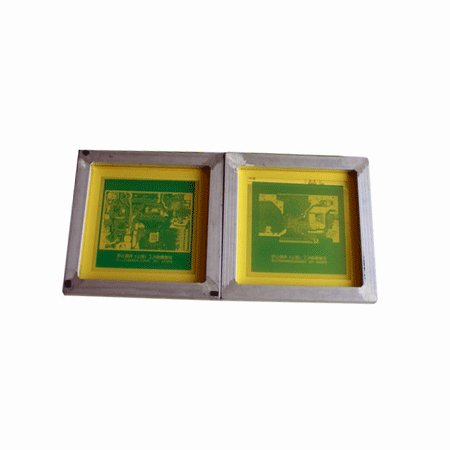

Emulsion for silk screen printing

Both solvent-based water-resistance, high sensitivity, high resolution of, the viaduct, solvent resistance and good softness omentum, printability and good quality screen Stripping regeneration.

For PCB, advertising signs, ceramic transfer paper, networks and high-precision screen printing screen. ;??

Characteristics: both solvent-based water-resistance, high sensitivity, high resolution of, the viaduct, solvent resistance and good softness omentum, printability and good quality screen Stripping regeneration. For PCB, advertising signs, ceramic transfer paper, networks and high-precision screen printing screen. Volume.

.Use Method︰

* Diazo mixture:

Diazo dissolution is about 10% of total weight of emulsion of water soluble until completely dissolved, mixed with emulsions. (Diazo dissolution can not use hot water. In addition, the container can not be used diazo dissolved metal containers.)

Diazo solution and the emulsion to stir, to prevent bubbles, stir placed a day or more with 250 mesh screen filter before use. Diazo added after dark in the cold preservation, use about 10 days.

* Coating:

Sensitive adhesive coating prior to wire-line to confirm that no dust.

KC Series with a bucket scraping coating, etc., with hand-painted or automatic coating machine coating, coating to prevent air bubbles entering the time.

* Dry:

Drying temperature below 40 ℃ for. (Drying temperature is too high, can lead to heat curing.) Using the SM-DC series bake edition boxes of dried.

* Exposure:

Using the KC-SM-UVE Series Shai Banji to copy, please refer to the emulsion exposure time exposure time of the page

* Developing:

Developing available water. All development of water wetting. Developing the use of pressurized water (spray gun, automatic developing machine, etc.) the most suitable.

In addition, the development has been soaked in water prior to curing some easy expansion off, affecting image quality.

Screen Mesh

|

Silk screen Width |

||||||

|

T/cm |

Mesh count/inch |

50〃/127cm |

54〃/136cm |

62〃/158cm |

86〃/220cm |

120〃/306cm |

|

KC12T-55 |

30mesh |

2.35 |

2.88 |

3.00 |

3.38 |

3.97 |

|

KC14T-55 |

35mesh |

2.21 |

2.50 |

2.65 |

3.18 |

3.53 |

|

KC16T-55 |

40mesh |

2.29 |

2.59 |

2.79 |

3.53 |

4.12 |

|

KC20T-55 |

50mesh |

2.35 |

2.88 |

3.00 |

3.38 |

4.06 |

|

KC24T-55 |

60mesh |

2.65 |

2.94 |

3.24 |

3.53 |

4.41 |

|

KC32T-55 |

80mesh |

2.35 |

2.50 |

2.65 |

3.24 |

4.26 |

|

KC39T-55 |

100mesh |

2.06 |

2.21 |

2.50 |

2.79 |

3.76 |

|

KC47T-55 |

120mesh |

2.35 |

2.50 |

2.79 |

2.94 |

4.41 |

|

KC53T-55 |

135mesh |

2.65 |

2.94 |

3.38 |

4.06 |

5.29 |

|

KC59T-55 |

150mesh |

2.79 |

3.09 |

3.53 |

4.41 |

5.88 |

|

KC64T-55 |

160mesh |

2.94 |

3.38 |

3.97 |

6.76 |

7.65 |

|

KC72T-48 |

180mesh |

4.41 |

4.56 |

4.85 |

8.24 |

9.41 |

|

KC80T-48 |

200mesh |

4.71 |

5.00 |

5.29 |

8.82 |

10.59 |

|

KC90T-48 |

230mesh |

6.18 |

6.76 |

7.35 |

11.18 |

13.53 |

|

KC100T-40 |

250mesh |

6.76 |

7.35 |

8.24 |

13.24 |

15.59 |

|

KC110T-36 |

280mesh |

9.41 |

10.00 |

11.18 |

18.24 |

20.00 |

|

KC120T-34 |

300mesh |

10.29 |

11.18 |

13.24 |

22.06 |

24.41 |

|

KC120T-36 |

300mesh |

9.41 |

10.59 |

12.35 |

21.47 |

23.53 |

|

KC120T-34 |

High precision |

11.76 |

13.53 |

16.47 |

26.47 |

28.82 |

|

KC140T-34 |

350mesh |

16.47 |

18.53 |

21.18 |

34.71 |

36.76 |

|

KC140T-31 |

High precision |

17.65 |

19.12 |

22.06 |

37.35 |

40.59 |

|

KC150T-31 |

380mesh |

24.12 |

26.47 |

27.94 |

52.94 |

55.88 |

|

KC165T-34 |

420mesh |

27.94 |

30.88 |

32.94 |

63.24 |

66.76 |

Usage︰

Made by PERT PA, Stainless steel; Fisrt cioating Elmulsion on the surface of silk, Have a UC exposure with UV exposure machine.

Technical Parameter︰

Production Advantage ︰

Use Method︰

* Choose the width of the screen, the device in the middle of La Machine's clip

* Put the screen frame on the workbench of machine;

* Taut the silk with Handle, and Push pneumatic switch and make the screen frame rise up to the top to contact with the screen

* Coating Adhesive glue .

* Till glue dry, loose Tighten machine, remove the screen plate.

Tension meter

|

The printed articles and the screen tension |

||

|

The type of screen |

The category of the printed article |

The silk tension (N/cm) |

|

Utra high-tension screen |

Circuit board and surveyor’s measure |

16-20 |

|

High-tension screen |

Multicolor and four colors overprint (1) |

16-20 |

|

High-precision and ultrafine screen |

Multilayer circuit in precisely print |

25-30 |

|

High-precision polyester screen |

Multicolor and four colors overprint (2) |

8-12 |

|

Common polyester screen |

Flat-smooth object |

8-12 |

|

Nylon screen |

Cylinder and rough surface object |

8-12 |

|

The max tension of different Mesh |

|||

|

Mesh/inch |

Mesh/cm |

The Max tensile force |

The atmospheric pressure |

|

77T |

200mesh count |

30N/cm |

7 Kg/cm |

|

90T |

230mesh count |

25N/cm |

6.5 Kg/cm |

|

100T |

250mesh count |

23 N/cm |

6 Kg/cm |

|

120T |

300mesh count |

21 N/cm |

5.7 Kg/cm |

|

140T |

350mesh count |

20 N/cm |

5.3 Kg/cm |

|

165T |

420mesh count |

18 N/cm |

5 Kg/cm |

Usage︰

In the process tighten silk, before coating the adhearing emlmusion between the silk and screen frame, Tensionmeter used to measure the tension of screen plat in order to get Precision Data.

Technical Parameter︰

Measure range: 0-35N/cm;

Telerance: 0.05N/cm

Use Method︰

1. After Tighten silk onto screen frame and before coating adhering Emulsion Glue;

2. Take a Tensionmeter and put it onto the five point of screen plate, measue the tension range;

3. If you find the tension is not come up to the requirment data, Please continue tighten the silk .

4. Store in drying and far from magnetic feild.

Coating tool

* Make sure All logo included in the coating section with the coater; more wider logo need more wider coater;

* Please make sure teh coater clean;

* This coater suitable for making small size screen plate, and suitable for making large size but lower quality screen plate.

Usage︰

With the coater, you will coat screen emulsion onto the surface of screen silk, This is important step of making screen plate.

Technical Parameter︰

Production Advantage ︰

Use Method︰

* Please choose the coater which width is a few than Width of logo on screen plate;

* Pour Emulsion with photosensitizer into the coater;

* Close the coater to the surface of screen and coating emulsion Evenly.

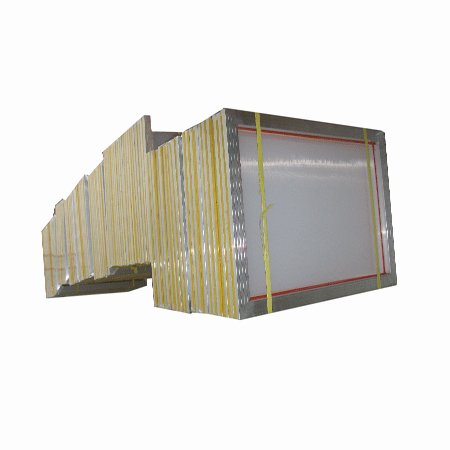

KC Aluminum Screen Frame

|

Size |

|

Size |

||

|

British |

Metric |

British |

Metric |

|

|

5×10 |

127×254 |

10×20 |

254×508 |

|

|

5×12 |

127×305 |

10×22 |

254×559 |

|

|

5×14 |

127×356 |

10×24 |

254×610 |

|

|

5×16 |

127×405 |

10×26 |

254×660 |

|

|

5×18 |

127×460 |

12×12 |

304×304 |

|

|

5×20 |

127×508 |

12×14 |

304×356 |

|

|

6×8 |

152×203 |

12×16 |

304×405 |

|

|

6×9 |

152×228 |

12×18 |

304×460 |

|

|

6×10 |

152×254 |

12×20 |

304×508 |

|

|

6×11 |

152×279 |

12×22 |

304×559 |

|

|

6×12 |

152×304 |

12×24 |

304×610 |

|

|

6×14 |

152×356 |

12×26 |

304×660 |

|

|

6×16 |

152×406 |

14×16 |

356×405 |

|

|

6×18 |

152×457 |

14×18 |

356×460 |

|

|

6×20 |

152×508 |

14×20 |

356×508 |

|

|

7×9 |

178×223 |

14×22 |

356×559 |

|

|

7×10 |

178×25 |

14×24 |

356×610 |

|

|

7×11 |

178×279 |

14×26 |

356×660 |

|

|

7×12 |

178×304 |

14×28 |

356×710 |

|

|

8×10 |

203×254 |

16×16 |

405×405 |

|

|

8×11 |

203×279 |

16×18 |

405×460 |

|

|

8×12 |

203×304 |

16×20 |

405×508 |

|

|

8×14 |

203×356 |

16×24 |

405×610 |

|

|

8×16 |

203×406 |

16×26 |

405×660 |

|

|

8×18 |

203×457 |

16×28 |

405×710 |

|

|

8×20 |

203×508 |

18×18 |

460×460 |

|

|

9×12 |

228×304 |

18×20 |

460×508 |

|

|

9×14 |

228×356 |

18×22 |

460×559 |

|

|

9×16 |

228×406 |

18×24 |

460×610 |

|

|

9×18 |

228×457 |

18×26 |

460×660 |

|

|

9×20 |

228×508 |

18×28 |

460×710 |

|

|

10×10 |

254×254 |

20×20 |

508×508 |

|

|

10×12 |

254×304 |

20×22 |

508×559 |

|

|

10×14 |

254×356 |

20×24 |

508×610 |

|

|

10×16 |

254×406 |

20×26 |

508×660 |

|

|

10×18 |

254×457 |

20×28 |

508×710 |

|