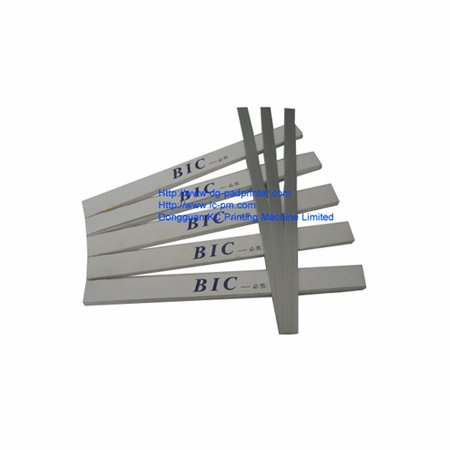

Pad Blade:

Description:

There are two kinds of thickness: one is 0.5mm, used by open inkwell pad printer, the other is 0.25mm, used by pad printer with resin plate.

Usage︰

Used by Open ink-tray pad printer to remove the ink on the surface of pad plate after coating ink with ink roller

Technical Parameter︰

Production Advantage ︰

Use Method︰

1. Check the quality of cutting of edge of blade;

2. Cut a more width than the pad plate installed on pad printer by a plier;

3. Install it to the nip of pad printer and fic it;

4. Adjust the pression between blade and plate.

Caution︰

Sharp cutting edge to break skin easily , Please avoid touching it carefully

Storage︰

1. Wrap it with paper or PVC film

2. Keep smooth state and prevent

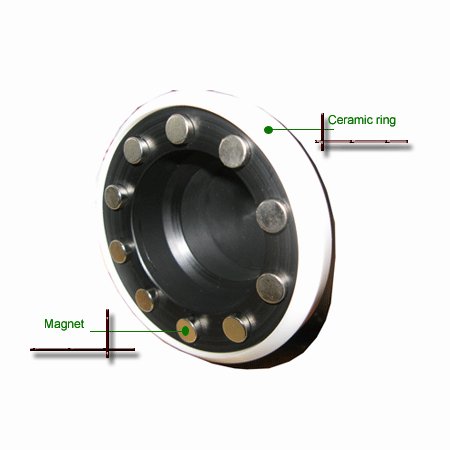

Sealed cup

|

Diameter |

Plate size |

Number |

Model of pad printer |

|

90mm |

100mm×200mm |

1 |

P1-408C TP1-408C P1-420C |

|

|

|

2 |

P2-408C |

|

|

100mm×250mm |

1 |

P1-410C 410MC |

|

|

|

2 |

P2-410C |

|

|

|

2 |

P2-41010C |

|

|

|

4 |

SP4-410C SP4-41016C |

| 6 | SP6-41018C | ||

|

|

100mm×300mm |

1 |

P1-412C |

|

|

|

2 |

P2-412C SP2-41210C |

|

|

|

4 |

SP4-412C SP4-41216C |

| 6 | SP6-41218C | ||

|

140mm |

150×400 |

1 |

P1-612C/614C/616C |

|

|

|

2 |

P2-612C/614C/616C |

|

|

|

4 |

SP4-612C/614C/616C |

|

|

|

6 | SP6-61222C/61422C/61622C |

Usage︰

Installed on the sealed cup pad printer to store ink and thinner; Meantime, Both Covering ink and removing ink function same as Steel blade. Sealed cup is consist of two parts: the Ink Cup ring and body part , The ring part of the installation in the cup body, wear occurs when the ring can be replaced. Now the knife ring are made of common two materials: ceramic and tungsten steel.

Technical Parameter︰

90mm diameter:

140mm diameter:

Production Advantage ︰

Use Method︰

Caution︰

There is sharp cutting edge which has high brittleness, Please aviod Collision and dropping; Because of Magnetism, When closing to steel objects, Please controlling speed.

Storage︰

Store in Pliable case made by Foam. Avioding contact with steel materials.

Inkwell

| Inch size | Metric Size | Quantity | Model |

| LC4"×4" | 100mm×100mm | 1 | 404M |

| 1 | P1-404 | ||

| 1 | TP1-404 | ||

| 2 | P2-404 | ||

| LC4"×6" | 100mm×150mm | 1 | 406M |

| 1 | P1-406 | ||

| 2 | P2-406 | ||

| 2 | SP2-40610 | ||

| 4 | SP4-406 | ||

| 4 | SP4-40616 | ||

| 6 | SP6-406 | ||

| 6 | SP6-40618 | ||

| 10 | SP10-40630 | ||

| LC4"×8" | 100mm×200mm | 1 | P1-408 |

| 2 | P2-408 | ||

| 2 | SP2-40810 | ||

| 4 | SP4-408 | ||

| 4 | SP4-40816 | ||

| LC4"×10" | 100mm×250mm | 1 | P1-610 |

| LC6"×6" | 150mm×150mm | 2 | P2-606 |

| 4 | SP4-606 | ||

| LC6"×8" | 150mm×200mm | 2 | P2-608 |

| LC6"×10" | 150mm×250mm | 2 | P2-610 |

Usage︰

Used by Inkwell pad printer . Install pad plate at the forth end and full of ink at the back end.

Coin Aluminum made.

In chinese market, Open inkwell pad printer widely used by customers because of its low price. There is key part of Open inkwell pad printer is inktray. It used to install pad plate and full of ink and thiner.

Technical Parameter︰

Production Advantage ︰

Fixture

Description:

Typically, the machine must be worth printing production supporting fixture, provide printed products, we will be based on user requirements and the printing process to produce the appropriate number of fixtures;

For color printing machine and printing machine shuttle run, just need to make a jig, fixture requirements of the general accuracy; the need to produce a rotary printing machine and work the same fixture the median number of requests for a repeat accuracy and location of the fixture consistency, otherwise it will affect the overlay accuracy.

Usage︰

Pad Printing and screen printing process to fix the product, to ensure the unity of the printing position, usually fixed to the fixture to the table to achieve the purpose. Printing machine needs a different fixture number is different.Production

Advantage ︰

Use Method︰

Adhering fixture with double-face tape onto working table of pad printer;

Fix fixture onto working table of pad printer with screw.

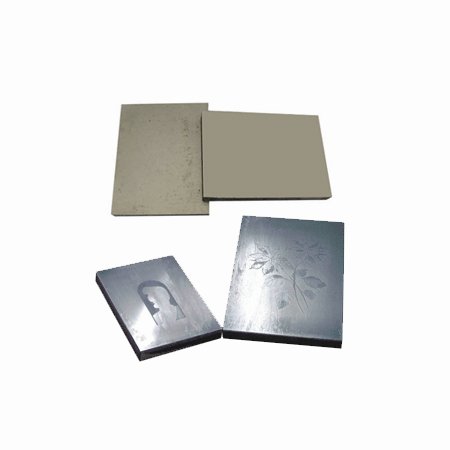

Putty

Making fixture of pad printing and screen printing, hot stamping;Suitable for some complex shape object.

Usage︰

Some objects with complex shape need fixture mde by KC Putty when pad printing and screen printing. At room temperature, Putty is mushy state, after adding the hardner, The mushy will be become to solid. When put object to be printed into the mixxing mixture, the mould will be formed, the shape is same as objects.

Use Method︰

Andard mixing ratio of KC Putty base and hardener is:Putty Base/Hardener=100/2(by weight)

Please mix them with KC adjustment spade. When mixxing a great amount , please use mixxing machine;

Milling base and Hardener thoroughly to make the color of mixture unifrom.

You must use the mixture within pot life(7-10min) , or the mixture will be solid and is invalidation .

Pot life changes depending on temperature and humidity. More higher temperature and lower humidity , the pot life more shorter;

Making one Paper mould base on objects to be printed, then pour the mixture into the paper mould, cover the object you want to print in the mixture;

Coating some mould release agent on the surface of object to help removing from the mixture;

After being solidify , please take a blade to repair to make the object easily to take off; the mixture will be solidify within 1 hours ad the temperature of 20 degree.

Storage︰