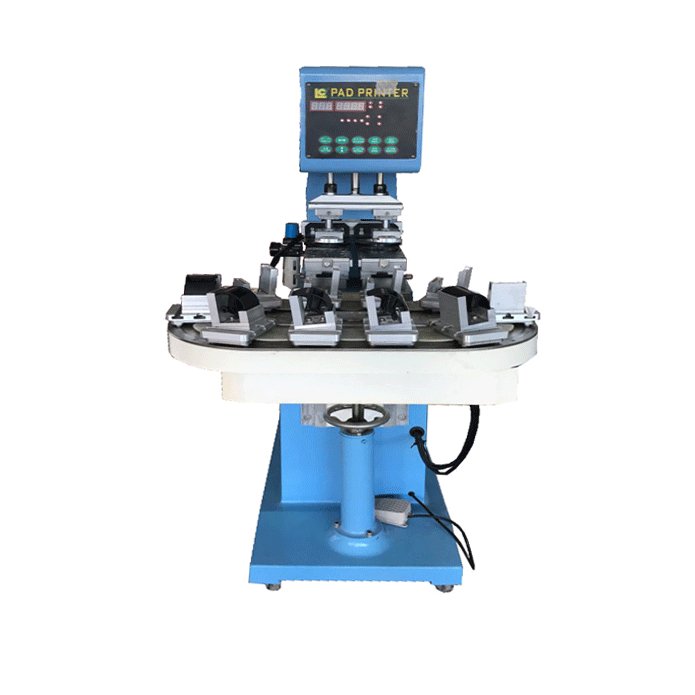

Model No.︰SP2-41010C

Brand Name︰LC

Country of Origin︰China

Unit Price︰US $ 3573 / pc

Minimum Order︰1 pc

Principle

The two-color turntable pad printer is a pneumatic pad printer with a 10-station turntable. First, two different colors of ink are placed in their respective oil cups, and the scraper evenly spreads the ink on two printing plates, on which patterns or texts of different colors are etched. Then, by rotating the turntable, medical equipment such as sphygmomanometers are sent to the bottom of the two pad heads in turn. Driven by the pneumatic device, the pad heads press down to absorb the ink, and then transfer the ink to the surface of the medical equipment, thus completing the two-color printing.

Structure

• Two-color oil cup and scraper: There are two independent oil cups, each holding ink of different colors, and each oil cup is equipped with a scraper to evenly distribute the ink on the printing plate.

• Printing plate: The two printing plates carry pattern information of different colors respectively, and their materials and production processes ensure that the patterns can be clearly transferred to the medical equipment.

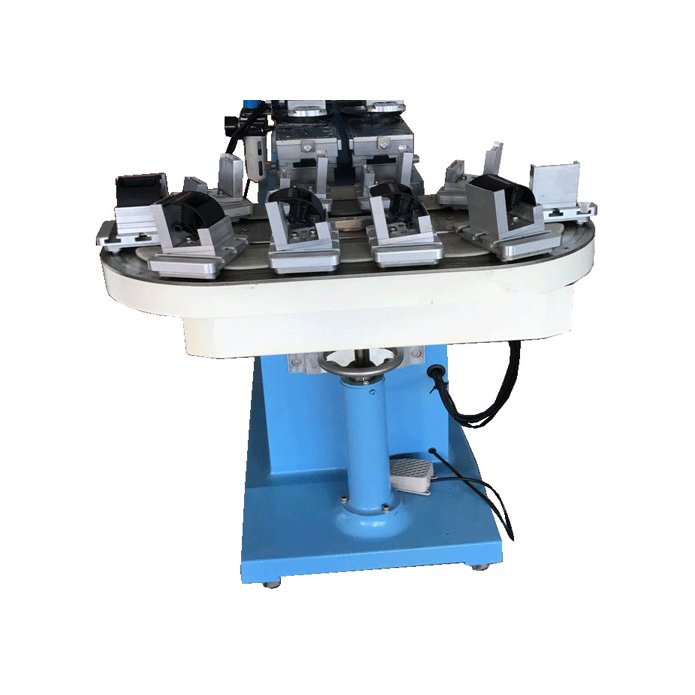

• Turntable: There are multiple stations on the turntable for placing medical equipment such as sphygmomanometers and thermometers. The turntable can rotate to send the equipment to different printing process positions in turn.

• Pneumatic device: including cylinder, air pipe and pneumatic valve, etc., which provide power for the up and down movement and forward and backward movement of the pad printing head, the rotation of the turntable, and the sliding of the oil cup, so as to ensure that the pad printing head can accurately absorb the ink and transfer it to the object.

• Pad printing head: usually made of soft and elastic materials such as silicone, which can well absorb the ink and transfer it to the curved or flat medical equipment.

Features

• Two-color printing function: it can realize the printing of two colors at the same time, enriching the appearance color of medical equipment, making it easier to distinguish different functions or display different information.

• High printing quality: the pneumatic device accurately controls the movement of the pad printing head, so that the ink is evenly transferred, the pattern is clear and complete, and the printing quality of the medical equipment is guaranteed.

• Efficient production: the turntable structure enables the equipment to operate continuously, improves production efficiency, and is suitable for mass production of medical equipment.

Application

• Logo and information display: printing brand logo, measurement range and other information on the sphygmomanometer, printing scale, unit, etc. on the thermometer, so that these information are clearer and more beautiful, and convenient for users to view.

• Functional differentiation and prompts: Through two-color printing, different functional areas or buttons of medical equipment can be distinguished, such as using different colors to represent different measurement modes or operation prompts, thereby improving the usability of the equipment.

|

Two colors pad printer with conveyer//Structure |

||

|

Feeding |

Manual |

|

|

Initial position |

Limited switch |

|

|

Working table |

10 stations conveyer-type working table |

|

|

Shuttle stroke |

125mm |

|

|

Ink supply system |

Closed -type system |

|

|

Plate type and size |

10mm Thick steel plate. |

|

|

Pad dropping control |

Simple-cylinder , simultaneously pressing |

|

|

Ink drying |

Heat air |

|

|

Blanking |

Manual |

|

|

Two colors pad printer//Usage and characters |

||

|

Guide |

|

|

|

Application fields |

Electrons, hardware, autos, toys, gifts, Plastics, household appliances, artwork, stationery, adornment, cosmetic, commodity, sport goods, decorative lightings, woodwork, office supplies, Photo Materials, Kitchen utensils, Hotel supplies, Computer, Mobile, etc., industrial field. |

|

|

Two colors pad printer with conveyer //Parameter |

||

|

Technical parameters |

SP2-41010C |

SP2-41210C |

|

|

|

|

Works supply |

|

|

|

Package list |

|

|

|

H.S.Code |

8443198000 |

|

|

Certicate |

CE |

|

|

Two colors pad printer with conveyer//Advantage |

||

|

Function |

|

|

Summary︰

The two-color pad printing machine is the most popular type of pad printing machine, and the rotary pad printing machine has improved its automation. The two-color rotary pad printing machine has always been the type that small and medium-sized enterprises like very much. The number of stations of the two-color pad printing machine ranges from 8-10, and 10 identical products can be installed to complete the printing of single-color or two-color products. The overprinting accuracy of the two-color rotary pad printing machine is higher than that of the four-color one.

Two-color pad printing machines are also divided into open type and closed type, and users can choose according to different needs.