Model No.︰S-900PV

Brand Name︰LC

Country of Origin︰China

Unit Price︰US $ 5500 / pc

Minimum Order︰1 pc

Thermal transfer film production process

Thermal transfer films include screen printing, gravure printing, and inkjet printing. Among them, screen printing is the most complicated. With the rise of DTF, the screen printing thermal transfer film process is facing a shrinking market trend. In some small printing companies, it still has a certain market share.

• Substrate film preparation: PET film is often used because of its good dimensional stability, uniform tension, heat resistance and good release properties.

• Release agent preparation: The release agent is a low-viscosity transparent resin with a fast solvent evaporation rate. When coating, the solid content should be controlled at about 23%, and attention should be paid to its transparency to avoid affecting the printing layer effect. The screen printing thermal transfer film is generally pre-coated with a release agent.

• Ink preparation: Thermal transfer inks are mostly solvent-based screen printing inks, which can be dried naturally or in a tunnel drying furnace.

• Adhesive preparation: Hot melt adhesive is commonly used as adhesive. After coating and drying to form a film, it has the advantages of high composite fastness, good flexibility, abrasion resistance, water resistance and acid and alkali resistance.

• Coating and drying: Coat the release agent, ink, adhesive, etc. on the substrate film, and then dry it to solidify the coating.

• Printing: Use screen printing and other methods to print the designed graphics on the coated substrate to obtain a printing layer.

Thermal transfer film flat screen printer

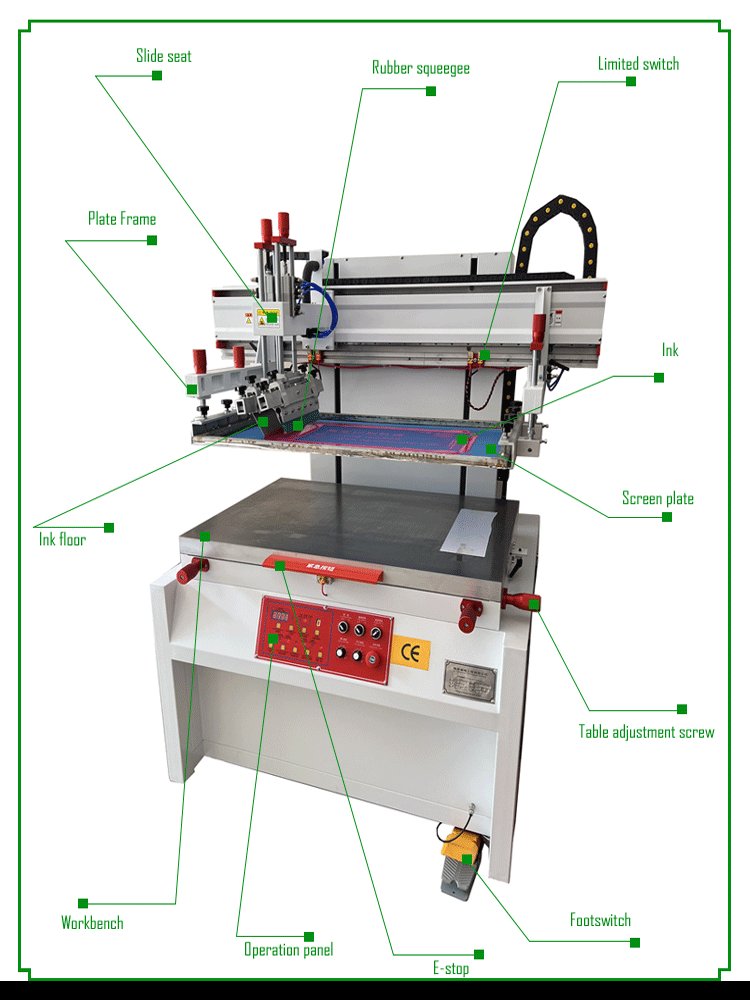

• Working principle: Through the extrusion of the scraper, the ink is transferred to the thermal transfer film through the mesh of the screen to form graphics.

• Structural composition: It is mainly composed of a control system, a screen printing system, a workbench, a pneumatic device, etc.

• Performance characteristics: high printing precision, can achieve multi-color overprinting; suitable for thermal transfer films of various materials; fast printing speed, high efficiency; easy operation and maintenance.

• Application areas: widely used in thermal transfer film printing in clothing, toys, plastics, metals and other industries, such as screen printing on roll materials such as PET, PVC, transfer paper, etc.

|

S-900PV Flat precision screen printing machine with vacuum table //Structure |

|

|

Location |

Vacuum adsorb, |

|

Working table |

Vacuum working table, Size: 700*1000mm |

|

Actions |

Up-down of screen plate |

|

To be printed |

|

|

Squeegee stroke |

Adjust the Limited switch |

|

Squeegee and screen plate control |

High precision linear guideway |

|

Blanking |

Manual |

|

S-900PV Flat screen printing machine with vacuum table //Usage and characters |

|

|

Guide |

|

|

Application |

|

|

S-900PV Flat screen printing Machine with vacuum table//Parameters |

|

|

Technical parameters |

S-900PV High-precision screen printing machine

|

|

Works supply |

|

|

Package parameters |

|

|

H.S.CODE |

8443192190 |

|

Certificate |

CE |

|

S-900PV Flat screen printing Machine with vacuum table //Advantage |

|

|

Function |

|

Summary︰

Semi-automatic flat screen printing machine in the market has a very large stock, its main advantages are widely used, cheap, easy to operate. There are two main types of flat screen printing machine, one is pneumatic, one is electric, electric flat screen printing machine refers to the mesh version up and down, scraper around the action have motor control, so faster, higher precision, operating panel has microcomputer type and touch screen type. Microcomputer panels are also larger in customer segments because they are easier to maintain and operate. There are also two types of flat screen press workbench, vacuum-inhale is the most common, it is suitable for printing paper, film and other products.