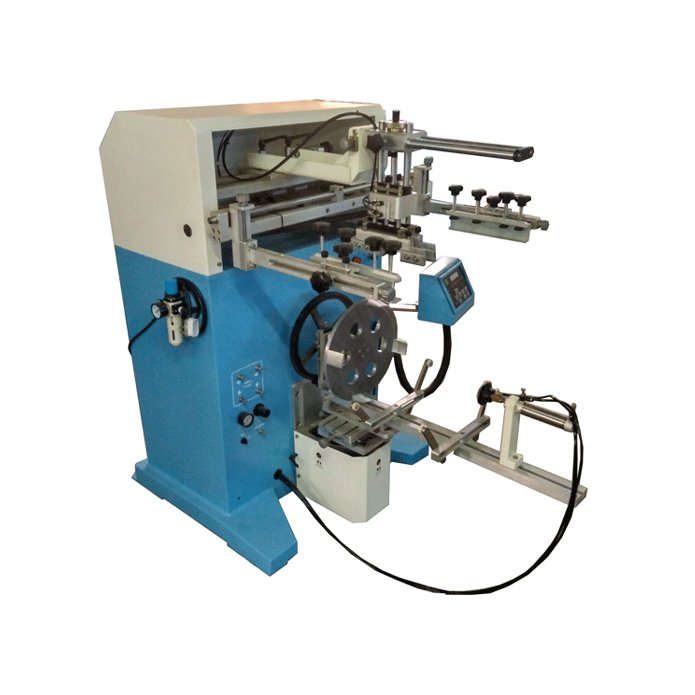

Model No.︰S-400N

Brand Name︰LC

Country of Origin︰China

Unit Price︰US $ 3044 / pc

Minimum Order︰1 pc

Special Mineral Water Bucket Clamp

This special clamp is specially designed for 5-gallon mineral water buckets. It can accurately fix the mineral water bucket to ensure that the bucket will not shake or shift during the screen printing process. The shape and size of the clamp are perfectly matched to the appearance of the mineral water bucket, tightly clamping the corresponding parts of the bucket, such as the barrel body or barrel neck, so that the pattern can be accurately printed at the predetermined position during screen printing, ensuring the quality of the screen printing and the integrity of the pattern.

Pneumatic up and down of the workbench

The pneumatic up and down method of the workbench has obvious advantages. Through pneumatic drive, the workbench can be raised and lowered quickly and smoothly. When preparing for screen printing, the workbench can be raised so that the mineral water bucket placed on it and fixed by the clamp can accurately fit the screen plate to ensure that the ink can be smoothly printed on the barrel through the screen plate; after printing is completed, the workbench can be smoothly lowered, which is convenient for removing the printed bucket or replacing the new bucket to be printed. The whole process is easy and efficient.

Microcomputer panel operation

The microcomputer panel serves as the control center of the entire screen printing machine. The operator can flexibly set a number of important parameters on the panel, such as the stroke and speed of the up and down movement of the workbench, the amplitude and frequency of the pneumatic left and right movement of the screen, etc. At the same time, the panel will also display the working status of the screen printing machine in real time, such as the current position of the screen, whether the printing operation is in progress, etc. Once a fault occurs, prompt information will be given in time, so that the operator can quickly make corresponding adjustments to ensure the smooth and accurate development of the screen printing work.

Pneumatic left and right of the screen

The screen relies on pneumatics to achieve left and right movement, which has strong power and easy to adjust the movement. During screen printing, the screen can move left and right at the set speed and amplitude. With the scraper (if any) and other components, the ink can be evenly passed through the pattern area on the screen and accurately printed on the surface of the 5-gallon mineral water barrel, ensuring that the printed pattern is clear and the color is uniform, meeting the requirements of high-quality screen printing.

Pneumatic screen printer for 5-gallon mineral water barrels

Overall, this screen printer is specially designed for the screen printing needs of 5-gallon mineral water barrels. Through the coordinated cooperation of various parts, it can efficiently and accurately print various patterns, logos or texts on mineral water barrels. Whether it is the company's brand trademark or some product descriptions and other information, it can be clearly printed on the barrel through it. It has strong practicality in the field of mineral water barrel packaging and printing.

|

S-400N Minerla bucket screen printing machine//Usage and characters |

|

|

Guide |

|

|

Application |

Plastics soft tubes, Bottles, containers, Bucket, Cosmetic case, any Cylinder-object, Oval-object. |

|

S-400N Multi-function screen printing Machine //Parameters |

|

|

Technical parameters |

|

|

Works supply |

|

|

Package parameters |

|

|

H.S.CODE |

8443198000 |

|

Certificate |

CE |

|

S-400N Mineral bucket screen printing Machine//Advantage |

|

|

Function |

|

Summary︰

Drinking water is related to the life and health of thousands of households and is the basis of food safety. Now, independently packaged drinking water accounts for almost all of the drinking water market, while most of the drinking water used by families and groups is packaged in 5-gallon containers made of polyester materials, and the shape and size are relatively standardized. Most of the mineral water barrels are not It is a pure cylinder, but has many ridges in the circumferential direction.

The printing of mineral water barrels is more common with labels, and many users also use screen printing. It is more convenient to use screen printing, and the printing process is relatively simple. The diameter of this kind of barrel is mostly about 200-300mm. If you want to print the entire circumference, you need to consider a large-size screen printing machine. However, more users do not require printing the entire circumference, but only a section of arc. So in small It is also common practice to modify large-sized curved screen printing machines. The left and right strokes of such screen printing machines do not need to be increased, but the height needs to be increased to ensure that the mineral water bucket can be placed on the workbench.

Since the size of the mineral water bucket has been standardized, the fixtures of the machine can also be basically standardized. In this way, after purchasing the machine, it can be printed directly after installing the screen and ink.