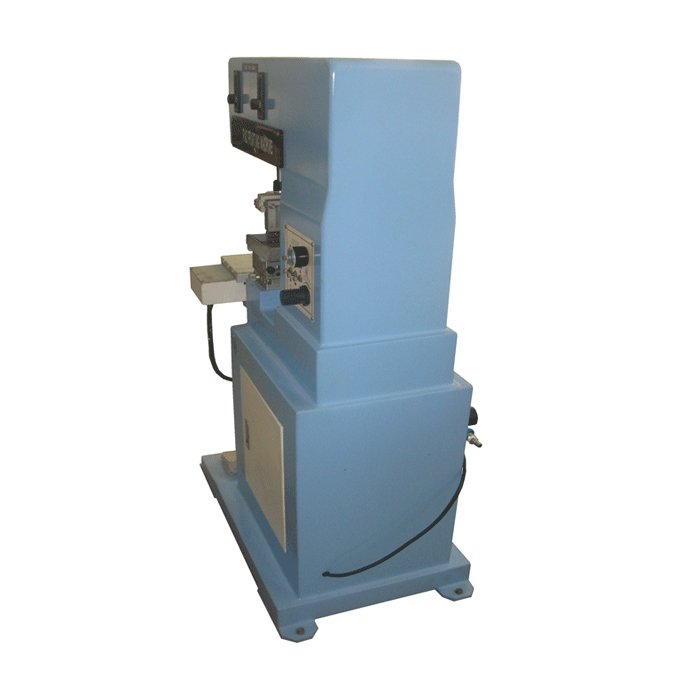

Model No.︰P2-406

Brand Name︰LC

Country of Origin︰China

Unit Price︰US $ 2074 / pc

Minimum Order︰1 pc

Pad printers for promotional items and office supplies :

Working Principle

First, place the promotional items or office supplies to be printed on the corresponding printing station and fix them. Set the relevant printing parameters, such as printing speed, two-color shuttle action sequence, etc. through microcomputer operation. During printing, the pad printing rubber head descends to dip the ink in the open oil tray, and then moves to the surface of the object for the first printing (single color). After that, with the help of the two-color shuttle function, the rubber head dips the ink again and moves to the corresponding position for the second printing, thereby achieving a two-color printing effect. After the printing is completed, the object can be taken out.

Main Structure and Features

• Two-color shuttle system: It is composed of mechanical transmission devices, guide rails, etc., which can accurately control the shuttle movement of the pad printing rubber head between different color ink areas and printing stations, ensure the accurate position of the two printings, achieve clear and accurate overprinting of the two-color pattern, and enhance the richness and beauty of the printing.

• Open oil tray: convenient for adding, observing and replacing ink, and the remaining amount and status of ink can be checked at any time. The ink is evenly distributed in the tray, which helps the pad printing rubber head to dip evenly, ensure the stable amount of ink for each printing, and make the printed pattern full and consistent in color.

• Microcomputer operation control system: equipped with an intuitive operation interface, the operator can easily set various parameters of the pad printing machine, such as printing speed, rubber head pressure height, interval time of two-color shuttle, etc., and can also realize automatic control, improve printing efficiency and accuracy, and also facilitate fault diagnosis and monitoring of the equipment.

Advantages

• Good printing effect: Two-color shuttle can achieve richer and more diverse color matching, meet the requirements of promotional products and office supplies for beautiful and eye-catching display, make printed patterns or texts more attractive, and help product promotion or office use.

• Convenient operation: The microcomputer operation is simple and easy to understand, and it can be operated without complex professional skills training, reducing manual operation errors, and can quickly adjust parameters according to the printing needs of different items, improving work efficiency.

• Wide range of applications: It can print promotional items (such as promotional ornaments, promotional gifts, etc.) and office supplies (such as stationery, folders, etc.) of various materials, shapes and sizes. By properly adjusting the rubber head, clamps and other components, it can flexibly adapt to different printing objects.

• Convenient ink management: The open oil tray makes the use and maintenance of ink simple, easy to clean and replace different colors and types of ink, reducing the cost of use and the difficulty of maintenance.

|

Two colors pad printer with shuttle//Structure |

||

|

Working table |

Two stations Shuttle-type working table |

|

|

Shuttle stroke |

125mm |

|

|

Ink supply system |

Open-type inkwell system |

|

|

Plate type |

10mm Thick steel plate. |

|

|

Pad dropping control |

Simple-cylinder , Continue pressing |

|

|

Ink drying |

Heat air |

|

|

Two colors pad printer// Usage and Characters |

||

|

Guide |

|

|

|

Application fields |

Electrons, hardware, autos, toys, gifts, Plastics, household appliances, artwork, stationery, adornment, cosmetic, commodity, sport goods, decorative lightings, woodwork, office supplies, Photo Materials, Kitchen utensils, Hotel supplies, Computer, Mobile, etc., industrial field. |

|

|

Two colors pad printer with shuttle//Parameter |

||

|

Technical parameters |

P2-404 |

|

|

||

|

P2-406 |

P2-408 |

|

|

|

|

|

Works supply |

|

|

|

Package list |

|

|

|

||

|

H.S.Code |

8443198000 |

|

|

Certicate |

CE |

|

|

Two colors pad printer with shuttle//Advantage |

||

|

Function |

|

|

Summary︰ The two-color shuttle pad printing machine is one of the best-selling types of pad printing machines. It can print almost all small-size products. It is low-priced, easy to operate, and easy to recover costs. The whole machine adopts an open ink tray structure, a workbench shuttle mechanism and Single chip operation panel with low maintenance cost.