Model No.︰PM2-200

Brand Name︰LC

Country of Origin︰China

Unit Price︰US $ 2397 / pc

Minimum Order︰1 pc

Lighter Pneumatic Shuttle Pad Printer

Structural Features

• Body: Mostly made of high-quality aluminum alloy, light and strong, the machine structure is made of aluminum alloy.

• Oil pan and rubber head: equipped with two oil pans, which can be adjusted separately, the color adjustment is simple and convenient, and there are independent rubber head up and down stroke and speed adjustment devices.

• Scraper system: Automatically balanced oil knife, scraping ink cleanly, easy to adjust, can improve production efficiency.

• Workbench: The workbench generally adopts a T-slot structure, which is convenient for installing various lighter fixtures to fix the product. The workbench can be adjusted in all directions such as up and down, left and right, front and back, and angle.

• Control system: The microcomputer controls each function action, the operation is simple and convenient, and the printing speed can be adjusted to meet different printing requirements.

Working principle

First, make the pattern or text to be printed into a printing plate, install it in the ink tray of the pad printer, add an appropriate amount of ink to the oil pan, and evenly apply the ink on the steel plate through the oil roller. After the machine is started, the pneumatic system drives the rubber head to descend, pick up the ink on the steel plate, then rise and move to the surface of the lighter, and then the rubber head descends again to print the ink on the lighter. After completing one-color printing, the shuttle table drives the lighter to move to the corresponding position of the oil pan on the other side to print another color, thereby realizing two-color overprint printing.

Advantages

• High printing quality: It can achieve accurate two-color overprint printing, with clear patterns, bright colors, and strong adhesion, which improves the appearance quality and grade of the lighter.

• Easy operation: Microcomputer control, the operation panel is simple and intuitive, and the operator can master the operation method of the machine after simple training, which reduces labor costs.

• Wide range of applications: Not only suitable for plastic lighters and metal lighters, but also for small pattern two-color overprint printing of stationery, toys, gifts, electrical appliances, electronics and other products.

• High production efficiency: The printing speed can be adjusted, up to 1800pcs/hr, and the machine runs stably and can work continuously for a long time.

|

Two colors pad printer with shuttle//Structure |

|

|

Initial position |

Limited switch |

|

Working table |

Two stations Shuttle-type working table |

|

Shuttle stroke |

125mm |

|

Ink supply system |

Open-type inkwell system |

|

Pad dropping control |

Simple-cylinder , Continue pressing |

|

Ink drying |

Heat air |

|

Blanking |

Manual |

|

Two colors pad printer// Usage and Characters |

|

|

Guide |

|

|

Application fields |

Electrons, hardware, autos, toys, gifts, Plastics, household appliances, artwork, stationery, adornment, cosmetic, commodity, sport goods, decorative lightings, woodwork, office supplies, Photo Materials, Kitchen utensils, Hotel supplies, Computer, Mobile, etc., industrial field. |

|

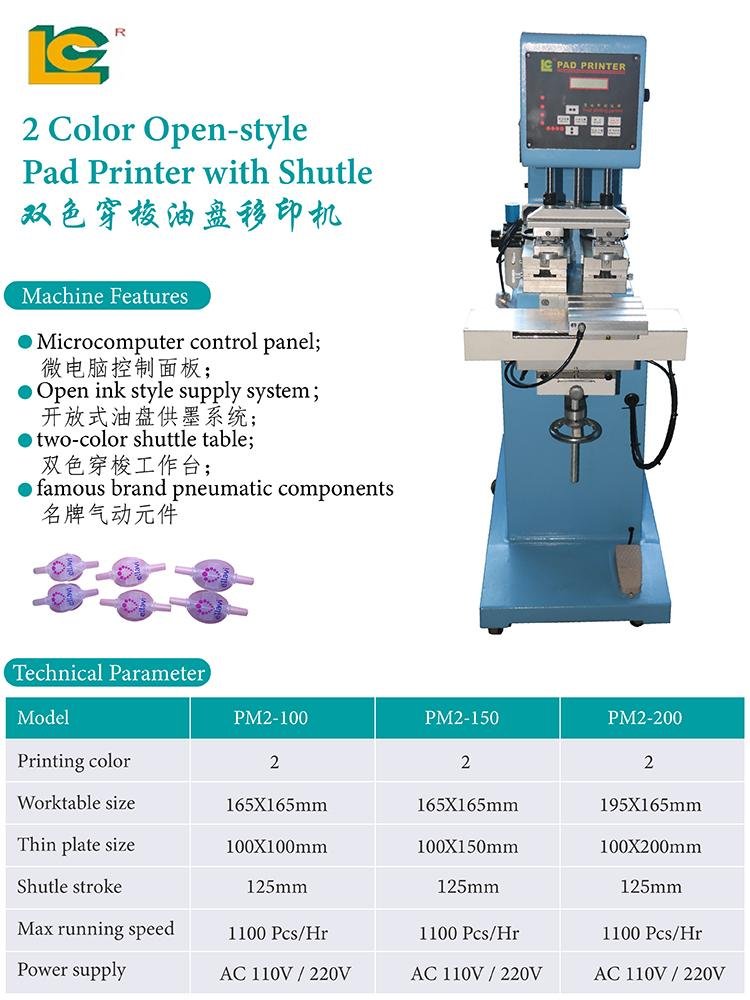

Two colors pad printer with shuttle//Parameter |

|

|

Technical parameters |

PM2-100 |

|

|

| PM2-150 | |

|

|

| PM2-200 | |

|

|

|

Works supply |

|

|

Package list |

|

|

H.S.Code |

8443198000 |

|

Certicate |

CE |

|

Two colors pad printer with shuttle//Advantage |

|

|

Function |

|

Summary︰

The two-color shuttle pad printing machine is one of the best-selling types of pad printing machines. It can print almost all small-size products. It is low-priced, easy to operate, and easy to recover costs. The whole machine adopts an open ink tray structure, a workbench shuttle mechanism and Single chip operation panel with low maintenance cost.