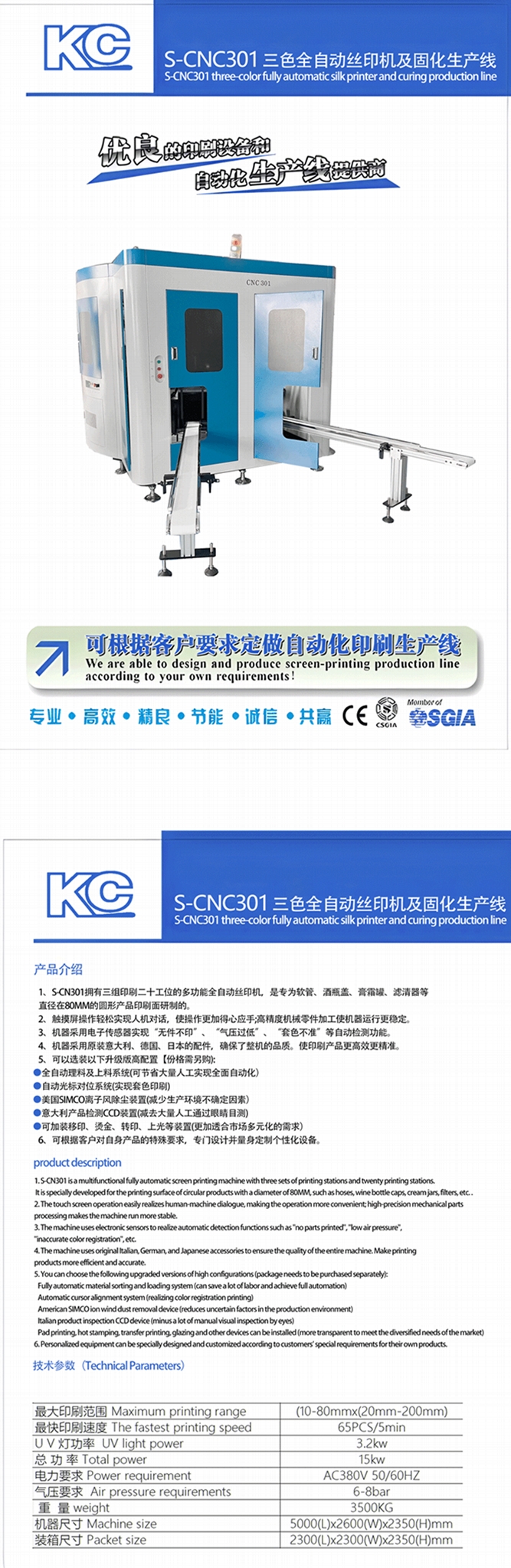

Model No.︰S-HR32UV6

Brand Name︰LC

Country of Origin︰China

Unit Price︰US $ 126470 / pc

Minimum Order︰1 pc

The full servo turntable CCD positioning glass wine bottle UVLED screen printer is an advanced equipment for glass wine bottle printing:

Structural composition

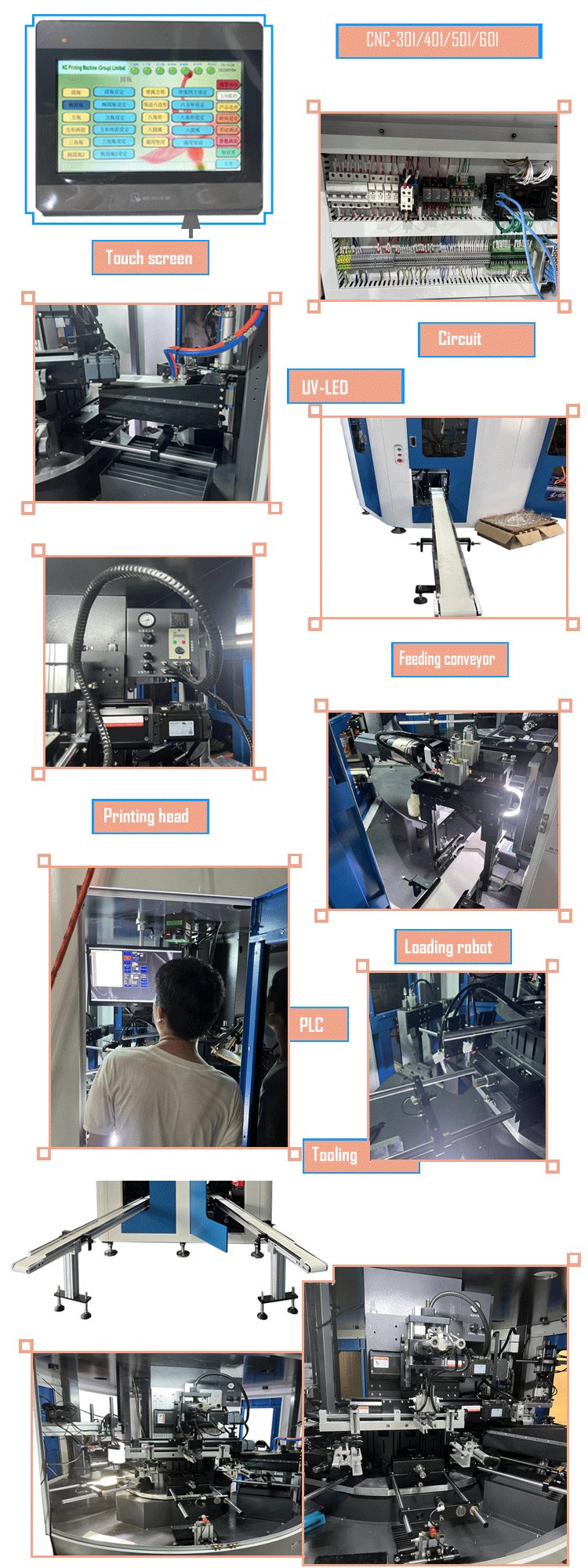

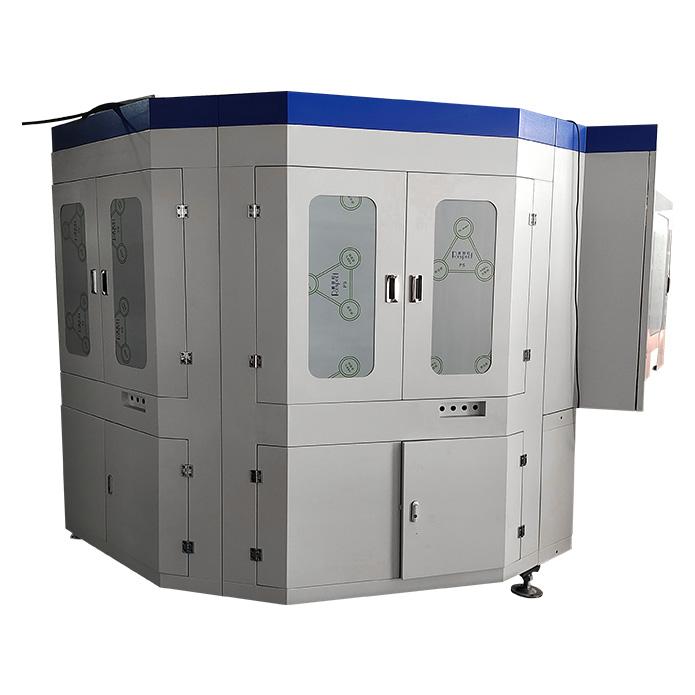

• Full servo flat turntable: The turntable is made of high-precision metal material with good rigidity and stability. It is driven by a full servo motor to accurately control the rotation angle and speed to achieve precise positioning of the workstation. The turntable is divided into multiple workstations for wine bottle loading, printing, drying, unloading and other processes. Each workstation is equipped with a positioning device to ensure the stable position of the wine bottle.

• CCD positioning system: It consists of a high-resolution CCD camera, lens, and light source. The CCD camera shoots the part of the wine bottle to be printed, the lens adjusts the focal length, and the light source provides uniform lighting. The system is connected to the control system, and the position, angle and printing pattern positioning point of the wine bottle are determined through image recognition. The feedback information is used to adjust the position of the screen printing plate to achieve precise printing.

• Screen printing system: includes screen printing plate, scraper plate, ink return plate and ink supply system. The screen printing plate is made according to the requirements of the wine bottle printing pattern. The scraper is made of wear-resistant material. It fits tightly with the printing plate to squeeze the ink during printing, and the ink return plate scrapes the remaining ink back. The ink tank of the ink supply system stores the ink, and the ink pump accurately delivers the ink to ensure the stability and uniformity of the ink supply.

• UV LED curing system: equipped with UV LED light source, installed after the printing station, the wine bottle enters the station immediately after printing, UV LED emits ultraviolet light of a specific wavelength to quickly cure the ink, improve production efficiency and printing quality, and is more energy-saving and environmentally friendly than traditional curing methods.

• Control system: With PLC as the core, combined with a touch screen operation interface. The operator can set parameters such as turntable speed, printing station residence time, screen printing plate movement position, scraper pressure and speed through the touch screen. The control system receives feedback from the CCD positioning system, automatically adjusts the printing position, and also has a fault alarm function.

Working Principle

Place the glass wine bottle on the turntable loading station. The turntable is driven by a full servo motor to transfer the wine bottle to the CCD positioning station. The CCD camera captures the image of the wine bottle and determines its position and the positioning point of the printed pattern, and feeds back to the control system. The turntable then sends the wine bottle to the printing station. The control system adjusts the position of the screen printing plate according to the feedback information. The scraper moves to squeeze the ink to complete the printing, and the ink return plate scrapes the ink back. After printing, the wine bottle enters the UV LED curing station, the ink is quickly cured, and finally the turntable transfers the wine bottle to the unloading station to complete the silk screen printing process. The operation can be cyclically operated to achieve mass production.

Features and Advantages

• High-precision printing: The full servo system is combined with the CCD positioning system, with high printing accuracy, and the pattern is accurately and clearly positioned on the wine bottle, which can meet the needs of high-end wine bottle packaging printing.

• Efficient production: The turntable design and the fast response of the full servo system make the silk screen printing process continuous and efficient, greatly improve production efficiency, and are suitable for mass production.

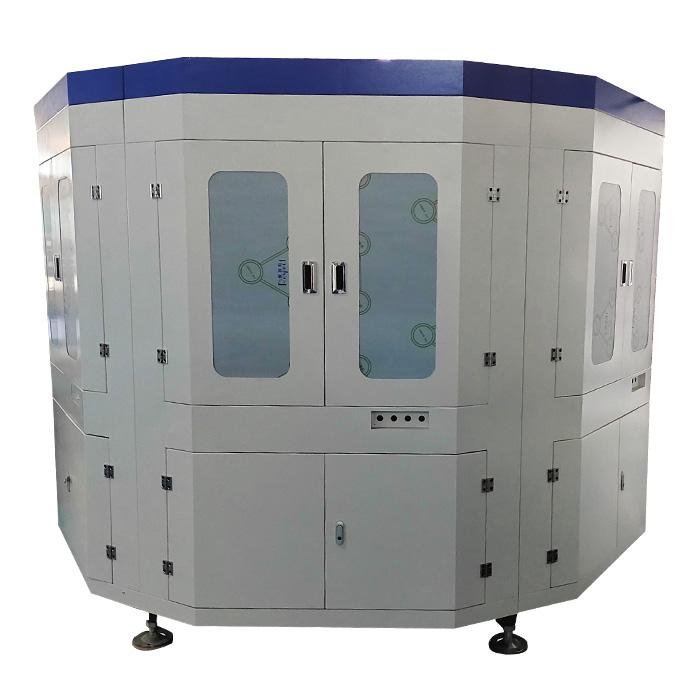

• High degree of automation: From wine bottle loading, positioning, printing to unloading, it is basically automated, reducing manual intervention, reducing labor intensity, and improving production stability and consistency.

• Wide applicability: It can adapt to the screen printing needs of glass wine bottles of different shapes, sizes and materials. By adjusting the CCD positioning system and printing parameters, high-quality screen printing can be performed on various wine bottles.

• Good curing effect: The UV LED curing system allows the ink to cure quickly, improves production efficiency and printing quality, and is energy-saving and environmentally friendly.

• Stable quality: The high-precision and automated control of the equipment ensures stable printing quality for each wine bottle and reduces printing defects.

|

S-HR32UV6 Full automatically Soft-tube screen printing machine/Structure |

|

|

Feeding device |

Conveyor, customized feeding system |

|

Direction identification |

Sensor, automatically identification |

|

Surface treatment |

Flame treatment, automatically lights |

|

Working table |

36-station stand rorating working table |

|

Actions |

Precision indexing disc Rotating transport |

|

Max Printing diameter |

70mm |

|

Max Printing Length |

200mm |

|

Rubber squeegee controlling |

High precision guide shaft |

|

Ink drying device |

UV Dying system |

|

Discharging |

Conveyor |

|

S-HR32UV6 Automatically Soft-tube screen printing machine//Usage and characters |

|

|

Guide |

|

|

Application fields |

|

|

S-HR32UV6 Full automatically screen printing Machine//Parameter |

|

|

Technical parameters |

|

|

Works supply |

|

|

Package list |

|

|

H.S.Code |

8443198000 |

|

Certificate |

CE |

|

S-HR32UV6 6-color full automatically screen printing machine//Advantage |

|

|

Function |

|

|

Main configuration |

|

Summary︰

It is a screen printing machine specially developed for plastic bottles and glass bottles. After manually placing the bottles on the feeding conveyor belt, the mechanical gripper transfers the bottles to the printing tooling. At the same time, the CCD camera captures the bottom and body of the bottle and cooperates with the servo motor for precise positioning. Two silk printing stations and two colors are completed at the same time. . Then the robot clamps the finished bottle to the unloading line. the

The machine has high efficiency, and the round bottle can reach more than 55 per minute, and the square bottle can reach more than 45 per minute. And the overprinting precision is high, the degree of intelligence is high, and the pass rate of product quality is high.

The main frame of the machine is welded by high-strength and high-quality steel parts, the circular turntable is designed, the main components are processed by CNC, and the plexiglass protective door is installed, which shows the safety of humanization and operation, and meets European safety standards; the control system , Servo motors, electrical components, and pneumatic components are all made of well-known brands from Germany, Japan, and France to ensure the accuracy and stability of the machine's operation. It is suitable for multi-color silk screen printing of round, square, square with arc, oval, rhombus, special-shaped and other bottle shapes.