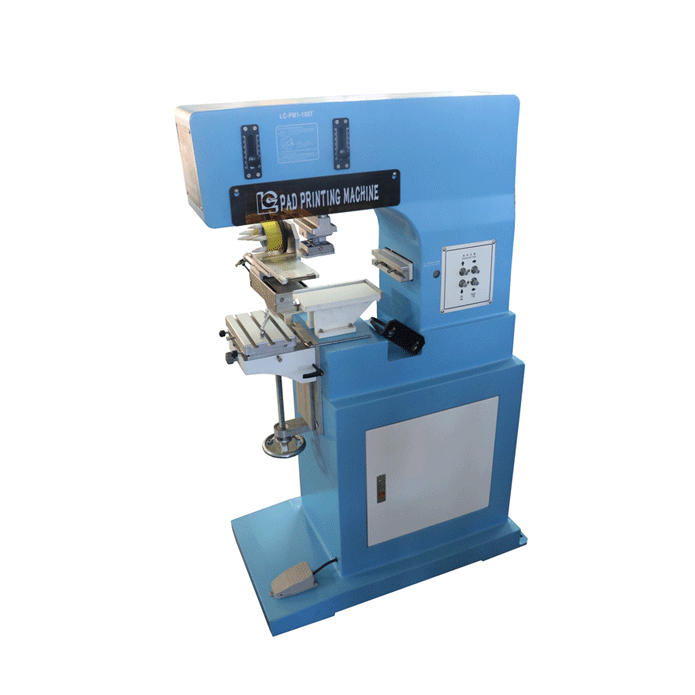

Model No.︰PM1-150TP

Brand Name︰LC

Country of Origin︰China

Unit Price︰US $ 2368 / pc

Minimum Order︰1 pc

Easy-to-adjust workbench

• The easy-to-adjust workbench brings great convenience to pad printing operations. For items of various shapes and sizes such as promotional items and daily necessities, operators can easily adjust the workbench according to actual needs, such as adjusting the height, angle, and horizontal position, to ensure that the items are in the best pad printing position, so that the ink can be accurately transferred to the corresponding position on the product surface, thereby ensuring the high quality of the pad printing effect.

Ink cup ink supply system

• The ink cup ink supply system plays a key role in the pad printing process. It can accurately and stably provide ink for pad printing, and through reasonable structural design, it can effectively control the flow and distribution of ink. When pad printing promotional items such as small fans and daily necessities such as combs, ink can be supplied on demand according to the size and complexity of the pattern to avoid blurring the pattern due to too much ink, or incomplete pattern due to too little ink, which helps to present a clear and full pad printing pattern.

Microcomputer operation panel

• The microcomputer operation panel makes the control of the equipment simple and intelligent. Operators only need to enter the corresponding parameters on the operation panel or select the preset mode to easily set the key parameters of pad printing, such as the speed of pad printing, the force of the rubber head pressing down, the amount of ink supplied by the oil cup, etc. In the face of promotional items and daily necessities of different materials and shapes, such as plastic toys and paper coupons, they can be quickly adapted through the microcomputer operation panel to reduce the difficulty of operation and improve the efficiency and accuracy of pad printing.

Air circuit control system

• The air circuit control system provides stable and accurate power for the relevant actions of the pad printing machine. It can control the actions of pressing down, lifting and moving the rubber head to ensure smooth movement and accurate positioning of the rubber head during pad printing. For example, when pad printing the curved parts such as the cup handle in daily necessities, the air circuit control system can accurately adjust the angle and force of the rubber head so that the rubber head fits well with the curved surface, achieving uniform and accurate ink transfer and ensuring the quality of pad printing.

Automatic cleaning device for rubber head

• The automatic cleaning device for rubber head helps to keep the rubber head in good condition and improve the continuity and stability of pad printing. After pad printing a product, ink is likely to remain on the pad. If it is not cleaned in time, it will affect the quality of the next pad printing. The automatic cleaning device can regularly clean the pad, remove excess ink and impurities, and ensure that the pad is clean. When batch pad printing is performed on promotional items and daily necessities, it can effectively avoid problems such as pattern defects caused by pad contamination, and ensure that the pad printing effect of each product can meet the standard.

Applicable scenarios

• This monochrome pad printer suitable for promotional items and daily necessities can play an important role in many scenarios. In shopping mall promotions, it can be used to pad print promotional patterns or texts on coupons and small gifts; in the production of daily necessities, it can pad print brand logos and decorative patterns for various plastic, paper, wood and other materials, such as combs, cups, packaging boxes, etc., to meet the company's needs for product appearance personalization, publicity and promotion.

The pad printing machine is an indirect printing process that realizes printing with the help of a soft pad printing pad. The pad printing pad continuously moves back and forth on the printing plate and the surface of the product to transfer ink, and a certain amount of ink will remain on the surface of the pad after repeated accumulation. Accumulation to a certain extent will affect the printing clarity, so the operator should often stop the machine to wipe the ink on the surface of the pad printing head. This action can now also be done automatically by installing an automatic rubber head cleaning device on the pad printing machine.

The automatic rubber head cleaning device is to install an automatically movable adhesive tape on the front or side of the steel plate. After the pad printing machine completes the set printing times, it prints on the tape once, and the remaining ink will be automatically removed. The automatic rubber head cleaning device reduces the steps for workers to manually clean the rubber head, reduces the manual intervention in the operation of the pad printing machine, and improves the printing quality. Now relatively high-end pad printing machines and automatic pad printing machines are basically equipped with this device, and the printing quality is further guaranteed.

|

One color pad printer with automatically pad-clean device //Structure |

||

|

Working table |

Standard working table with 3-size adjustment |

|

|

Ink supply system |

Closed -type system |

|

|

Plate type |

10mm Thick steel plate. |

|

|

Pad dropping control |

Simple-cylinder , simultaneously pressing |

|

|

One color pad printer//Usage and characters |

||

|

Guide |

|

|

|

Application fields |

Electrons, hardware, autos, toys, gifts, Plastics, household appliances, artwork, stationery, adornment, cosmetic, commodity, sport goods, decorative lightings, woodwork, office supplies, Photo Materials, Kitchen utensils, Hotel supplies, Computer, Mobile, etc., industrial field. |

|

|

One color pad printer //Parameter |

||

|

Technical parameters |

PM1-100TP |

|

|

||

|

PM1-150TP |

PM1-200TP |

|

|

|

|

|

Works supply |

|

|

|

Package list |

|

|

|

H.S.Code |

8443198000 |

|

|

Certificate |

CE |

|

|

One color pad printer //Advantage |

||

|

Function |

|

|

Summary︰

1..The pad printing machine is a typical indirect printing process that relies on a pad printing head to transfer ink between the plate and the product. Since the pad printing head cannot achieve complete deinking, a part of the ink may remain on the surface of the glue head, causing printing defects.

2. For those less expensive pad printers, the operator often stops the machine to wipe the rubber head to improve the printing effect.

3. However, there are also quite a number of pad printing machine factories that install an automatic rubber head cleaning device on the pad printing machine to automatically realize this function, which not only improves the printing quality, but also saves the labor intensity of the operator.

4. The automatic rubber head cleaning device is a small device with adhesive tape fixed. After printing, the printing rubber head is first returned to the top of the adhesive tape to simulate the printing action. The adhesiveness of the adhesive tape can easily peel off the ink and achieve cleaning. Features.