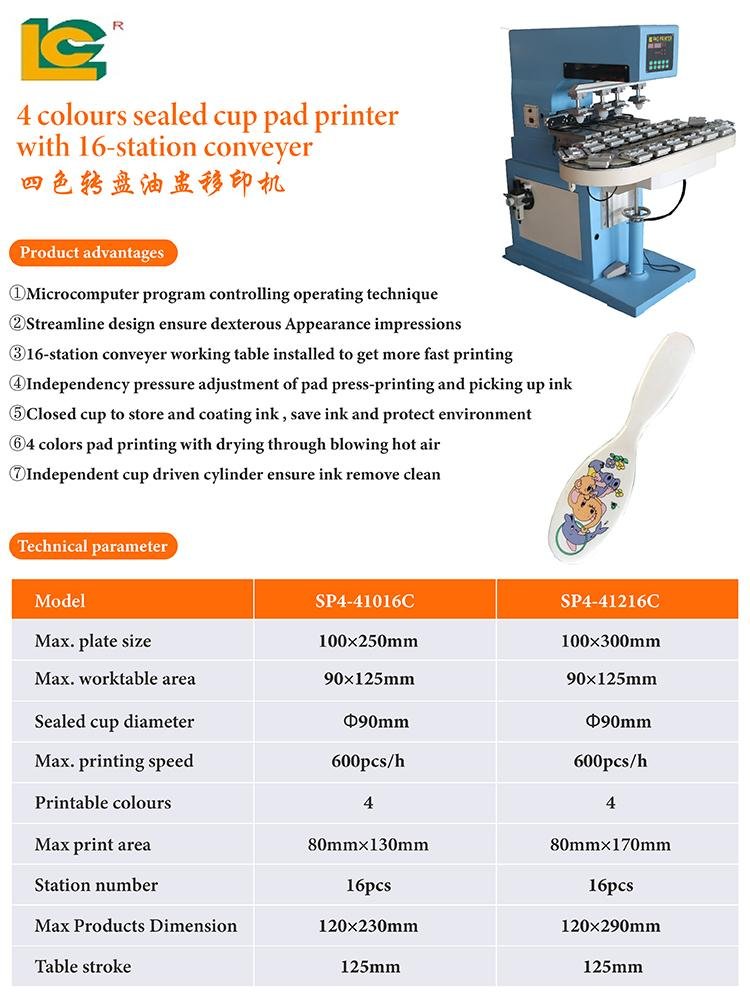

Model No.︰SP4-41216C

Brand Name︰LC

Country of Origin︰China

Unit Price︰US $ 5382 / pc

Minimum Order︰1 pc

Golf ball four-color turntable pad printer:

1. Basic principle

The working principle of the golf ball four-color turntable pad printer is to use the transfer characteristics of the silicone head. First, the pattern or text is made on the printing plate through platemaking technology, and there are four corresponding color areas on the printing plate (for four-color printing). The silicone head of the pad printer descends and contacts the printing plate, absorbs the ink on it, then lifts and moves above the golf ball, and descends again to transfer the ink to the surface of the golf ball. Through the rotation of the turntable, the golf ball passes through four pad printing stations of different colors in turn to complete the four-color printing.

2. Structural composition

• Turntable system: This is one of the core parts of the machine. The turntable is usually driven by a high-precision motor that can accurately control the rotation angle and speed. There are multiple golf ball clamps on the turntable to fix the golf ball, ensure the stability of the ball position during the pad printing process, and enable the pattern to be accurately printed on the surface of the ball.

• Pad printing head system: It includes multiple silicone pad printing heads, the shape, hardness and elasticity of which are carefully designed to ensure that the ink can be well absorbed and evenly transferred to the golf ball. The movement of the pad head is controlled by a precise cylinder or motor to achieve up and down and horizontal movement, thereby completing the ink transfer from the printing plate to the golf ball.

• Printing plate system: There are four printing plates, corresponding to four colors (such as CMYK mode). The production quality of the printing plate directly affects the printing effect. It is usually made of metal or photosensitive materials. The pattern and text parts on its surface can absorb ink, while the non-pattern parts are specially treated and will not absorb ink.

• Ink supply system: Responsible for providing ink to the printing plate, including ink tank, scraper and ink circulation device. The scraper can evenly distribute the ink on the printing plate and scrape off the excess ink to ensure that the amount of ink absorbed each time the pad head contacts the printing plate is uniform. The ink circulation device can keep the ink in good fluidity and uniformity.

• Control system: It is the brain of the entire pad printing machine. It is generally controlled by a microcomputer. The parameters such as the speed of the turntable, the movement trajectory and speed of the pad head, and the ink supply of the printing plate can be set through programming. The operator can make adjustments according to the printing requirements of the golf ball, and the control system can also realize automated production and improve production efficiency.

3. Application advantages

• High-precision printing: It can achieve high-precision four-color printing on the curved surface of golf balls, making the patterns and texts clear, colorful, and distinct, greatly improving the appearance quality and brand recognition of golf balls.

• High production efficiency: Through the rotation of the turntable, multiple golf balls can be pad printed in sequence, and the movement of each pad printing head can be precisely controlled, reducing manual operation time and errors, which is suitable for mass production of golf balls.

• Strong flexibility: According to different design requirements, the printing plate can be replaced and the position of the pad printing head can be adjusted to conveniently print various patterns, trademarks and texts to meet the personalized requirements of different customers.

|

4 colors pad printer with 16-station conveyer//Structure |

||

|

Working table |

16-station conveyer-type working table |

|

|

Shuttle stroke |

125mm |

|

|

Ink supply system |

90mm diameter Closed cup type system |

|

|

Plate type |

0.3mm Thin steel sheets plate. |

|

|

Pad dropping control |

Simple-cylinder , Continue pressing |

|

|

Ink drying |

Heat air |

|

|

4 colors pad printer//Usage and characters |

||

|

Guide |

|

|

|

Application fields |

Electrons, hardware, autos, toys, gifts, Plastics, household appliances, artwork, stationery, adornment, cosmetic, commodity, sport goods, decorative lightings, woodwork, office supplies, Photo Materials, Kitchen utensils, Hotel supplies, Computer, Mobile, etc., industrial field. |

|

|

4 colors pad printer with 16-station conveyer//Parameter |

||

|

Technical parameters |

SP4-41016C |

SP4-41216C |

|

|

|

|

Works supply |

|

|

|

Package list |

|

|

|

H.S.Code |

8443198000 |

|

|

Certicate |

CE |

|

|

4 colors pad printer with conveyer //Advantage |

||

|

Function |

|

|

Summary︰

The oil cup pad printing machine with four-color turntable is also a relatively popular type. It is equipped with a 90mm diameter ink cup, which saves ink and is more environmentally friendly. It uses the oil cup to independently push the cylinder, and the scraping ink is cleaner; Pneumatic turntable, more products can be installed, saving product preparation time; Microcomputer control panel is adopted, the operation is more simple; it can print 1-4 colors, widely used in toys, gifts, decorations, handicrafts, etc. and daily life Related product pad printing.