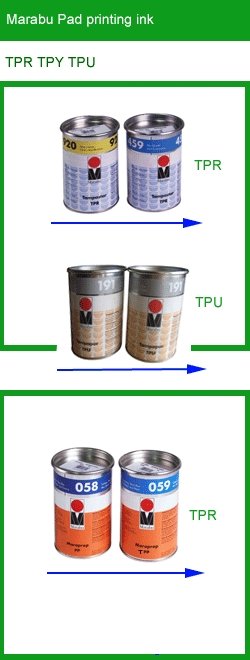

Although screen printing ink is able to be used by the pad printer. Appropriative pad ink is recommended by the pad printing expert because of steady surface tension and nice ink transfer result. There are three kinds of pad inks in Chinese pad printing market.

The process of pad printing ink transfer is briefly described as follows: first pour the oil pan into the oil pan, and then the ink will be coated on the surface of the printing plate driven by the inking device; the scraper will scrape off the ink coated on the surface of the printing plate, as shown in the figure The ink in the text will remain in the pit; the pad printing head moves to the top of the printing plate to stick the ink in the pit of the printing plate; the pad printing rubber head moves to the substrate to print the ink on the product surface.

The process of pad printing ink filling the pits of the printing plate requires that the pad printing ink has good fluidity and cannot be dried before the pad printing rubber head is dipped; after the ink is dipped by the pad printing head, it must be ensured that the ink has sufficient plasticity, that is, the ink cannot There are changes in form. The transfer of ink on the surface of the rubber head is similar to the release state of the thermal transfer film, which must be completely transferred without major changes.

Pad printing ink requirements:

1. Fast and stable drying.

Compared with screen printing ink, the drying speed of pad printing ink is faster. If the drying speed is too slow, the transferability will be affected, but this is relative. If the drying speed is too fast, the ink will dry on the printing plate. deep. In addition, it is very important for the pad printing ink to have a more stable drying speed range. When the ink is brought from the oil pan into the printing plate, transferred to the surface of the rubber head, and printed on the surface of the product, the amount of ink transferred is very small. To ensure the stability of printing suitability, the ink must maintain a stable drying speed, so the purity of the solvent in the pad printing ink should be higher than that of the screen printing ink.

2. The color concentration of pad printing ink is higher.

The ink layer of pad printing ink is similar to that of offset printing. In order to obtain brighter colors, the color concentration of the pigment in the ink must be high, but too high a color concentration means that the adhesion will decrease. Obviously, we will have to refine the molecules of the pigment And choose better resin to make up for this deficiency.

3. Pad printing ink has more stable colloidal properties.

Ink is a kind of suspension, and it will appear delamination when it is left for a long time. A uniform amount of ink is obtained on the head surface, which is similar to offset printing ink properties.