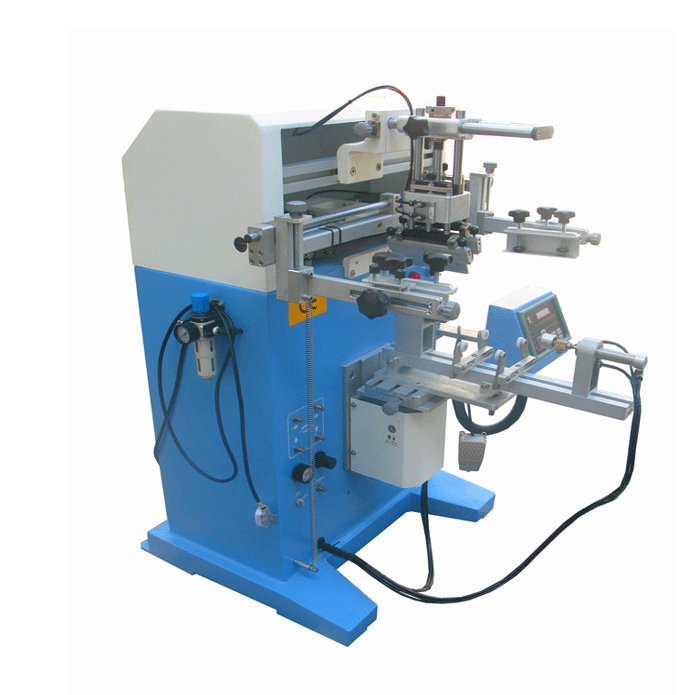

Model No.︰S-75S

Brand Name︰LC

Country of Origin︰China

Unit Price︰US $ 1544 / pc

Minimum Order︰1 pc

Disposable cup screen printer

Principle

When the multifunctional pneumatic screen printer is working, first pour the ink into one end of the screen, and then move the scraper on the screen. By applying pressure, the ink passes through the mesh on the screen, and the ink is transferred to the surface of the cups such as milk tea cups and tea cups, so as to complete the printing. The pneumatic system provides power for the up and down movement of the workbench, the left and right movement of the screen, and the positioning and movement of the cup to ensure accurate and stable printing.

Structure

• Screen: There are meshes made according to the printed pattern or text on it. It is the key part for the ink to pass through and form the pattern. At the same time, it is equipped with an aluminum screen frame to ensure its stability.

• Scraper: The scraper is used to push the ink to move on the screen, so that the ink is evenly distributed and passes through the mesh.

• Pneumatic device: It includes solenoid valves, cylinders, air pipes and various pneumatic valves. It controls the air pressure to realize the up and down movement of the screen printing head and the up and down movement of the workbench. It is an important power support for the machine to realize automatic operation.

• Cup fixture: a device for placing various cups such as milk tea cups. The fixture can be set with an air blowing structure or without air blowing. The fixture can ensure parallel contact between the screen and the mother line of the cup.

• Microcomputer operation panel: The operation panel contains operation buttons for various parts of the machine. During the debugging process, it can be used to operate a single action. When the printing effect meets the requirements, it can be operated in pneumatic automatic mode.

Application scenarios

• Milk tea cup: brand logo, special milk tea flavor pattern, promotional information, etc. can be printed to make the milk tea cup more recognizable and attract consumers' attention.

• Tea cup: print elegant tea culture element patterns, tea cup names, producers and other content to add cultural charm and brand characteristics.

• Coffee cup: print coffee brand logo, coffee bean pattern, different roasting degree logo and various patterns and texts related to coffee culture to enhance brand image.

• Disposable paper cups and disposable plastic cups: in addition to printing basic business information and brand logo, you can also print holiday themes and customized blessings according to different occasions. It is suitable for various activities, gatherings and other scenes.

Advantages

• Versatility: It can be adapted to a variety of cups of different materials and shapes for printing to meet diverse market needs. Whether it is a paper cup or a plastic cup, high-quality printing can be achieved.

• Good printing quality: With the help of precise control of the pneumatic device, the ink can be evenly transferred, the pattern is clear, the color is bright, and the adhesion is strong, it is not easy to fade, and the printing effect is long-lasting.

• Easy operation: Parameters are set through the microcomputer operation panel, the operation is intuitive and convenient, and the operator can get started after simple training, which reduces labor costs and operating difficulties.

• High production efficiency: Pneumatically driven automated operation, combined with effective positioning of the cup fixture, can achieve continuous and rapid printing, suitable for mass production of various cups to meet the large market demand.

For the printing of cylinders, elliptical cylinders, cones, especially hollow plastic containers, the most preferred choice is the curved surface screen printing machine. The curved surface screen printing machine transfers the left and right movement of the flat screen to the curved surface product through gear transmission or friction transmission. For the printing machinery on the linear contact surface, the continuous rotation of the product, and the part in contact with the surface will continuously receive the ink transfer on the screen to achieve printing.

The significant difference between the curved surface screen printing machine and the flat screen printing machine is that its fixture actually completes the rotation of the product, and the rotation process is in linear contact with the movement of the screen, and no slippage can occur. Therefore, the main elements of the curved screen printing machine are: screen printing screen, screen printing ink, screen printing squeegee, and the squeegee on the curved screen printing machine is usually a squeegee with a triangular cross-section. The screen printing jig has various forms, and its main feature is to ensure the precise and stable rotation of the product.

The curved screen printing machine can print tiny cylinders such as straws and pen refills with a diameter of 1mm, and can also print plastic barrels, oil barrels, and water heater shells with a diameter of more than 500mm. Screens and fixtures will do.

|

S-75S Multi-function screen printing machine//Usage and characters |

|

|

Guide |

|

|

Application |

Plastics soft tubes, Bottles, containers, Bucket, Cosmetic case, any Cylinder-object, Oval-object. |

|

S-75S Multi-function screen printing Machine //Parameters |

|

|

Technical parameters |

|

|

Works supply |

|

|

Package parameters |

|

|

H.S.CODE |

8443198000 |

|

Certificate |

CE |

|

S-75S Multi-function screen printing Machine//Advantage |

|

|

Function |

|

Summary︰

The most popular printing method for round and oval products is screen printing, and semi-automatic screen printing machines are the best-selling screen printing machines. Every year, more than 1,000 semi-automatic curved screen printing machines are sold from China to the world. Although in recent years, sales have increased The squeeze of the automatic screen printing machine continues to decrease, but it is still the model favored by small and medium enterprises worldwide.

The semi-automatic curved screen printer can print almost all cylinders and ellipsoids, involving almost all materials, and the diameter of the largest printed product can reach 1M. When it is used with flame treatment and UV curing machine, it is another contribution to environmental protection. The semi-automatic screen printing machine can only print one color at a time, and overprinting up to 10 colors can be achieved through positioning. It is also particularly suitable for printing on containers that are not suitable for automatic screen printing machines such as milk bottles and special-shaped bottles.